Road markings are essential for traffic safety, providing guidance, lane separation, and visual communication for drivers and pedestrians. Behind these bright, durable lines are two primary application technologies: thermoplastic marking machines and cold paint marking machines. Each serves specific project needs, budgets, and performance expectations.

Introduction to Road Marking Systems

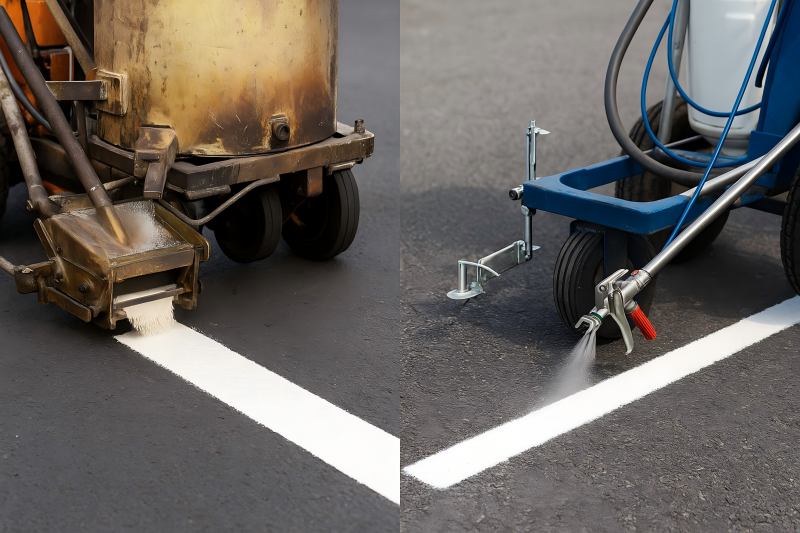

Before comparing the machines, it’s vital to understand what distinguishes thermoplastic markings from cold paint markings.

Thermoplastic markings are made from solid powders or granules that are melted to 180–220°C and applied hot. When cooled, they form a thick, wear-resistant film bonded to the pavement. These markings are widely used on highways, intersections, and high-traffic roads.

Cold paint markings, in contrast, use liquid paints applied at ambient temperature—either solvent-borne or water-borne. The paints are sprayed onto surfaces and dry through evaporation. These are common in parking lots, low-traffic roads, or temporary markings.

Working Principles of Each Technology

Thermoplastic Marking Machine

Thermoplastic machines apply a molten mixture of resin, glass beads, and pigments onto the pavement. The setup includes:

- Preheater: Melts and stirs the thermoplastic material.

- Applicator: Spreads the molten mix evenly using a screed shoe, extrusion system, or airless spray.

- Glass Bead Dispenser: Drops beads on the molten surface for retroreflectivity.

- Temperature Control System: Ensures the material remains within the correct working range.

The material quickly cools and solidifies, creating a durable road layer.

Cold Paint Marking Machine

Cold paint machines spray liquid paint—either water-based or solvent-based—onto the road surface. They typically use:

- Airless spray guns for uniform film thickness.

- Pressurized paint tanks for consistent flow.

- Optional glass bead systems for reflective markings.

- Stencil or handheld guns for symbols and lines.

Cold paint dries at ambient temperature, requiring minimal setup and maintenance.

Material Composition Comparison

| Parameter | Thermoplastic Road Marking | Cold Paint Road Marking |

| Base Material | Synthetic resin, pigments, glass beads, fillers | Acrylic, alkyd, or chlorinated rubber paint |

| State Before Application | Solid granules or powder | Liquid |

| Application Temperature | 180–220°C | Ambient (20–30°C) |

| Film Thickness | 1.5–3.0 mm | 0.3–0.6 mm |

| Drying Mechanism | Cooling and solidification | Solvent or water evaporation |

| Retroreflectivity | Excellent (embedded beads) | Moderate (surface beads) |

| Durability | 2–4 years | 6–18 months |

Thermoplastic markings are thicker and more resilient due to their resin structure and strong bonding properties, while cold paint systems offer faster, easier applications at lower cost.

Machine Components Overview

Thermoplastic Marking Machine Components

- Melting kettle (preheater) for preparing materials.

- Application shoe or extruder for uniform line width.

- Glass bead dispenser for reflectivity.

- Heating burner system for temperature control.

- Wheels and frame for mobility and precision.

Cold Paint Marking Machine Components

- Paint tank for holding liquid material.

- High-pressure pump (airless system) for spraying.

- Spray guns and nozzles for line control.

- Bead applicator (optional) for visibility.

- Manual or ride-on chassis for flexible operation.

While thermoplastic machines are more complex and require preheating, cold paint systems are lightweight, portable, and easy to maintain.

Application Scenarios

| Use Case | Thermoplastic Marking Machine | Cold Paint Marking Machine |

| Highways & Expressways | ✅ Excellent – Long-lasting and high visibility | ⚠️ Short lifespan under heavy traffic |

| Urban Roads & Intersections | ✅ Excellent – Durable under vehicle load | ⚠️ Fades quickly due to abrasion |

| Parking Lots & Warehouses | ⚙️ Possible but not economical | ✅ Ideal – Quick, simple, low-cost |

| Temporary Road Markings | ❌ Not suitable | ✅ Easy to remove or repaint |

| Cold or Humid Weather Conditions | ⚠️ Requires dry pavement and heat | ✅ Better adaptability |

| Budget Projects | ❌ Higher initial cost | ✅ Lower cost per job |

Thermoplastic machines are built for longevity and heavy-duty use, while cold paint systems are ideal for short-term or low-traffic applications.

Performance Characteristics

Durability

Thermoplastic markings can withstand vehicle friction, UV exposure, and temperature fluctuations for several years. In contrast, cold paint tends to wear off faster due to its thinner film.

Reflectivity

Thermoplastic markings embed glass beads during the molten stage, ensuring consistent retroreflectivity even after years of use. Cold paint relies on surface beads, which wear off faster.

Maintenance Frequency

Thermoplastic lines require re-application every 3–5 years, while cold paint often needs re-striping every 6–12 months, depending on traffic volume.

Drying & Curing

- Thermoplastic: Cools and solidifies in 3–5 minutes.

- Cold paint: Dries in 10–30 minutes (or longer under high humidity).

Cost Analysis and Lifecycle Economics

Initial cost isn’t the only factor—maintenance and re-striping frequency matter. Thermoplastic systems cost more upfront but save through durability and longevity.

| Cost Factor | Thermoplastic Machine | Cold Paint Machine |

| Initial Equipment Cost | High (includes melting kettle) | Low to moderate |

| Material Cost | Higher per ton | Lower per liter |

| Labor Intensity | Skilled operators required | Easier operation |

| Service Life | 2–4+ years | 0.5–1.5 years |

| Maintenance Frequency | Low | High |

| Overall Lifecycle Cost (per 3 years) | Lower for high-traffic roads | Lower for small-scale jobs |

For large infrastructure projects, thermoplastic markings offer superior return on investment. Cold paint is best suited for low-cost, frequent repainting scenarios.

Environmental and Safety Aspects

Thermoplastic Marking Machines

| Pros | Cons |

| No VOC emissions during curing.

Longer lifespan reduces overall waste. |

Requires fuel heating (energy-intensive).

High operating temperature poses burn risks. |

Cold Paint Marking Machines

| Pros | Cons |

| Low-temperature operation, safer for crews | Frequent repainting increases material waste |

| Water-based paints are eco-friendly with very low VOC emissions | Solvent-based versions emit VOCs, affecting air quality |

Thermoplastic technology is more energy-consuming, but its long-term durability can offset the environmental impact of frequent repaints.

Skill and Maintenance Requirements

Thermoplastic Machine Operators

- Must monitor heating temperatures and viscosity.

- Need training in safety protocols for handling molten materials.

- Must clean preheater tanks and nozzles regularly.

Cold Paint Machine Operators

- Simpler operation; quick to learn.

- Regular cleaning with water (for water-based) or solvent (for alkyd paints).

- Occasional nozzle replacement or pressure calibration required.

Advantages and Disadvantages Overview

| Aspect | Thermoplastic Marking Machines | Cold Paint Marking Machines |

| Durability | Very high (2–4 years) | Moderate (0.5–1.5 years) |

| Reflectivity | Excellent | Good |

| Application Complexity | High (requires heating) | Low (simple spray) |

| Cost Efficiency | High over long term | Cost-effective short term |

| Environmental Impact | Energy-intensive, low VOC | Water-borne: eco-friendly |

| Best For | Highways, intersections, permanent lines | Parking lots, temporary markings |

| Maintenance Needs | Low | High |

| Operator Skill Level | Skilled | Basic |

Choosing Between Thermoplastic and Cold Paint Machines

When selecting your marking equipment, consider the following criteria:

Traffic Conditions

- High traffic areas → Thermoplastic

- Low traffic or indoor areas → Cold paint

Project Duration

- Long-term, permanent markings → Thermoplastic

- Temporary or short-term markings → Cold paint

Climate

- Hot and dry climates favor both systems.

- Wet or cold climates favor cold paint (no heating required).

Budget

- If you have the budget for long-term investment, thermoplastic offers better value over time.

- For smaller or recurring projects, cold paint is ideal due to its flexibility and low startup cost.

Labor and Equipment

- Thermoplastic machines require trained operators and heavy-duty equipment.

- Cold paint machines are lightweight and can be operated by small crews.

Case Study Example

Let’s consider two scenarios:

Case 1: City Highway Project

- Traffic Volume: Heavy (20,000+ vehicles/day)

- Expected Line Life: Minimum 2 years

- Marking Requirement: 50 km of solid and dashed lines

- Chosen System: Thermoplastic

- Reason: Durability and reduced repainting frequency outweigh higher initial costs.

Case 2: Shopping Mall Parking Lot

- Traffic Volume: Light (under 1,000 vehicles/day)

- Expected Line Life: 6–12 months

- Marking Requirement: 3,000 m² area

- Chosen System: Cold paint

- Reason: Fast, cost-effective application with easy repainting.

Maintenance and Reapplication Practices

Thermoplastic Markings:

- Clean surface debris before application.

- Reapply once reflectivity drops significantly.

- Inspect adhesion annually, especially after harsh winters.

Cold Paint Markings:

- Clean with high-pressure water before repainting.

- Recoat as color fades or bead loss reduces visibility.

- Keep paint stored in cool, dry conditions.

Future Trends in Road Marking Technology

- Hybrid Markings: Combining cold-applied plastic resins (e.g., MMA) with glass beads for faster curing and higher reflectivity.

- Automated Marking Robots: GPS-guided systems for precise, consistent lines.

- Eco-Friendly Paints: Eco-friendly water-based and biodegradable thermoplastic road paints are gaining popularity.

- Smart Reflective Beads: Improved microstructure for consistent night visibility and reduced energy waste.

Final Comparison Summary

| Category | Thermoplastic | Cold Paint |

| Application Temperature | Hot (180–220°C) | Ambient |

| Film Thickness | 1.5–3 mm | 0.3–0.6 mm |

| Durability | 2–4 years | 6–18 months |

| Cost (Initial) | Higher | Lower |

| Cost (Lifecycle) | Lower over time | Higher over time |

| Operation Skill | Requires trained operators | Easy for beginners |

| Reflectivity | Excellent | Moderate |

| Environment | Low VOC, high energy | Low VOC (if water-based) |

| Best For | Highways, crosswalks, city roads | Parking lots, temporary lines |

Both thermoplastic and cold paint marking machines play vital roles in road marking projects. The right choice depends on your application scenario, budget, and durability needs.

- Choose thermoplastic marking machines for permanent, high-traffic applications requiring long-lasting visibility and minimal maintenance.

- Choose cold paint marking machines for temporary or low-traffic areas where fast application, flexibility, and affordability matter most.

In essence, thermoplastic = performance and longevity, while cold paint = simplicity and versatility. Understanding their differences helps ensure every kilometer of your markings delivers the safety, durability, and cost-effectiveness your project demands.