Thermoplastic Marking Machine

Our Thermoplastic Marking Machines deliver durable, reflective lines that withstand heavy traffic and harsh weather.

Engineered for professional road contractors, we offer efficient heating, smooth application, and precise control for faster projects, reduced downtime, and superior results.

- Dry Fast and Highly Wear-resistant

- Offer Excellent Retroreflectivity

- 10-15KG Bead Box Capacity

- 0-15km/h Marking Speed

- Hand Push or Ride-on Options

What Materials Can Thermoplastic Paint Machine Use?

Our thermoplastic road marking machine applies hot-melt thermoplastic and, depending on configuration, handles various related materials.

Thermoplastic Marking Powder

- Forms durable, wear-resistant road lines.

- Applied hot for quick drying.

- Ensures long-lasting visibility and performance.

Glass Beads (Reflective Material)

- Improves night-time visibility.

- Reflects headlights for safety.

- Dropped onto hot thermoplastic markings.

Primer (Adhesion Promoter)

- Enhances bonding to surfaces.

- Essential for concrete roads.

- Applied before thermoplastic coating.

What’s Marking Method of Thermoplastic Marking Machine?

Our thermoplastic marking machine offers screeding, extrusion, and spraying methods, ensuring precise, reflective, and versatile road markings for diverse applications.

Screeding Type

- Spreads molten material evenly with screed shoe.

- Produces flat, neat, consistent lines.

- Ideal for urban roads and intersections.

Extrusion Type

- Forces material through extrusion head.

- Creates thick, highly reflective markings.

- Perfect for highways and heavy-traffic roads.

Spraying Type

- Sprays material using compressed air.

- Suitable for thinner, complex markings.

- Fast application, flexible for various patterns.

What Operating Modes of Thermoplastic Paint Machine Can We Provide?

Our thermoplastic marking machines offer manual hand-push for small, flexible projects or self-propelled operation for efficient, stable, large-scale marking.

Hand push thermoplastic road marking machine

- Operated manually with low costs and simple maintenance.

- Ideal for small projects and repairs.

- Lightweight, flexible for narrow spaces.

Self-propelled thermoplastic road marking machine

- Powered drive improves marking efficiency.

- Suitable for medium to large projects.

- Reduces labor, ensures stable line quality.

Featured Products

SHM-310

SHM-320

SHM-300

SHM-330

Model | SHM-300 | SHM-310 | SHM-320 | SHM-330 |

Kettle capacity | 100KG | 100KG | 100KG | 100KG |

Bead box capacity | 10KG | 10KG | 10KG | 15KG |

Marking width | 100-450mm | 100-450mm | 100-450mm | 100-450mm |

Marking thickness | 1.0-3.0mm | 1.0-3.0mm | 1.0-3.0mm | 1.0-3.0mm |

Marking speed | 0-3km/h | 0-3km/h | 10-15km/h | 0-3km/h |

Walking style | Hand push/moped | Hand push/moped | American Breton 5.5HP | Hand push/moped |

Heating temperature |

| 180-220℃ |

| 180-220℃ |

Heating method | Liquefied petroleum gas | Liquefied petroleum gas | Liquefied petroleum gas | Liquefied petroleum gas |

Machine weight | 135KG | 135KG | 135KG | 147KG |

Dimensions | 1320*850*1000 mm | 1320*850*1000 mm | 1500*1200*700 mm | 1200*850*1200 mm |

Applications

Road and Highway Line Marking

- Lane markings, including center lines, edge lines, and stop lines

- Pedestrian crossings, arrows, speed limits

- Highways, expressways, rural roads, and urban streets

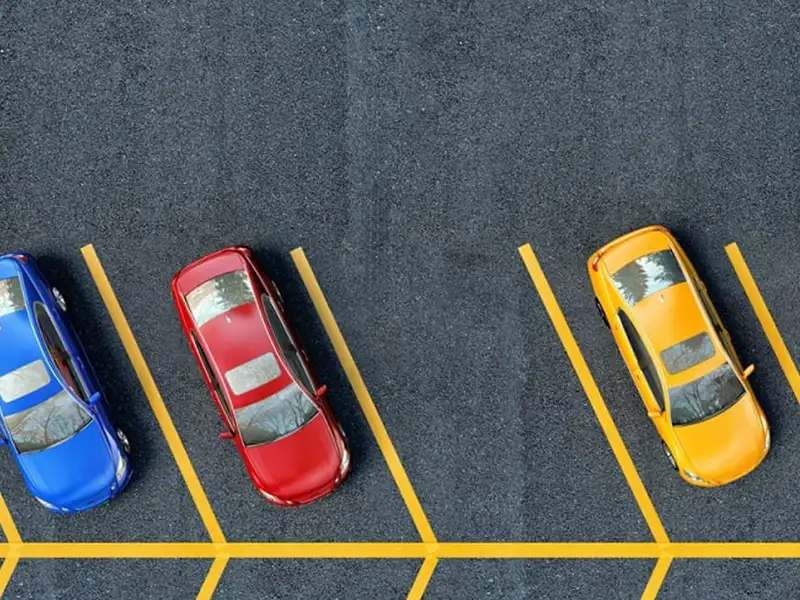

Parking Lot & Car Park Applications

- Marking parking bays, directional arrows, and pedestrian walkways

- Designating reserved areas like handicapped and EV charging spots.

- Suitable for both outdoor lots and multi-level parking structures

Municipal & Public Infrastructure

- School zones and playground safety markings

- Bus lanes, bicycle lanes, taxi stands

- Airport runways, taxiways, and aprons

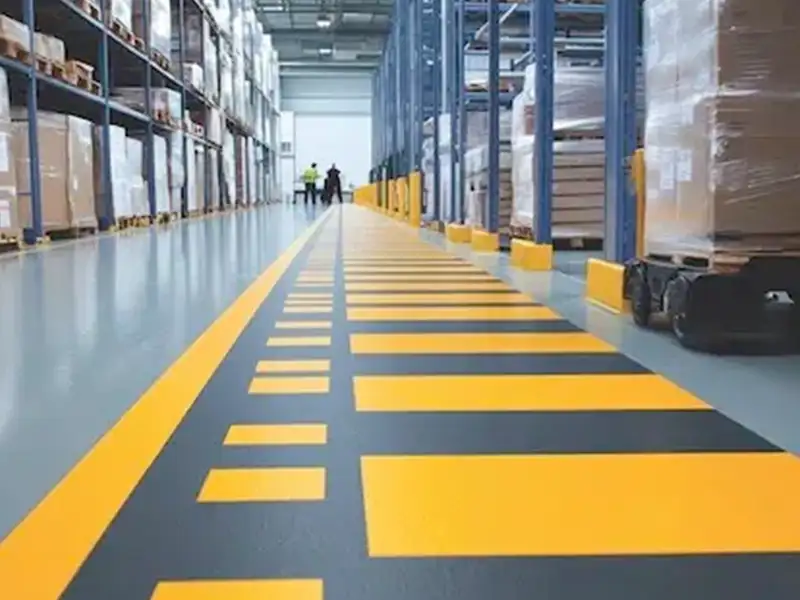

Industrial & Private Facilities

- Warehouse floors and logistic centers (safety lines, pathways)

- Factory internal traffic control and loading zones

- Ports, terminals, and logistics hubs

FAQ

Could you specify the type of heating system the machine uses?

We use LPG or diesel burners with efficient thermal insulation to ensure uniform heating of the thermoplastic material, maintaining the ideal application temperature during operation.

Can the line width and thickness be adjusted?

Yes. The machines allow quick adjustments of line width (e.g., 50–450 mm depending on the model) and thickness to meet different national road marking standards.

What’s the typical output capacity?

Capacity varies by model: Hand-push: 100–200 m²/day. Self-propelled: 400–800 m²/day.

Do you provide customization services?

Yes. We can customize tank capacity, line width modules, glass bead dispensers, and marking shoes according to your country’s standards or project needs.

What after-sales support can customers expect from your company?

We offer comprehensive support through technical manuals, video tutorials, online assistance, and spare parts supply. For large orders or government projects, on-site training can be arranged.