Concrete vibrators are essential equipment in the construction industry, ensuring that freshly poured concrete settles evenly and air pockets are removed to improve the strength and integrity of the structure.

Why Are Concrete Vibrators Essential?

Concrete, by nature, contains air bubbles when freshly mixed. If not properly consolidated, these trapped air voids compromise its strength and durability, potentially leading to cracking, structural failure, and reduced lifespan.

Concrete vibrators help eliminate these voids by transmitting vibration into the mix, encouraging particles to settle more densely and evenly. This results in:

- Enhanced structural strength

- Better surface finish

- Increased durability

- Reduction in honeycombing

- Better bonding with reinforcements

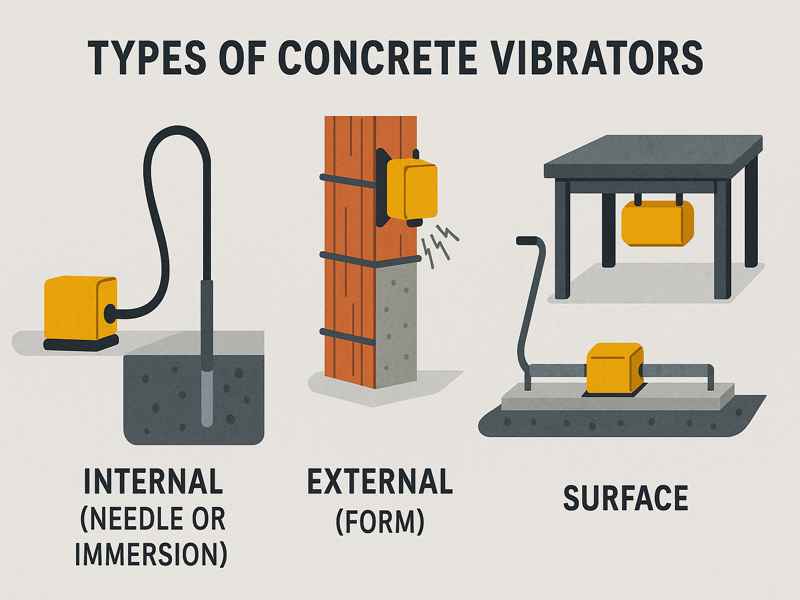

Main Types of Concrete Vibrators

Concrete vibrators can be classified based on their design, method of vibration, and application. The four main types include:

- Internal Vibrators (Needle/Poker Vibrators)

- External Vibrators (Shutter Vibrators/Form Vibrators)

- Surface Vibrators (Screed or Pan Vibrators)

- Vibrating Tables

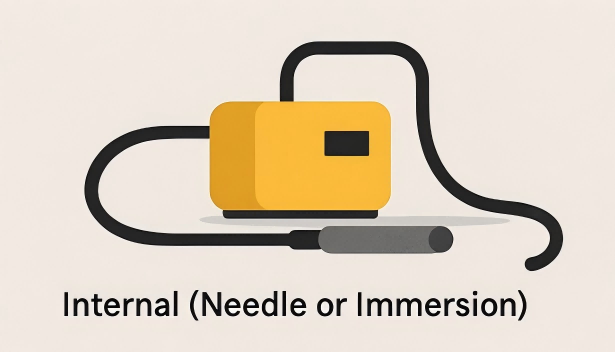

Internal (Needle or Immersion) Vibrators

Internal, needle, or immersion vibrators are the most commonly used. They consist of a vibrating head (the poker) connected by a flexible shaft to a power source.

Working Principle:

The head is inserted directly into freshly poured concrete. Vibrations are generated mechanically, electrically, or pneumatically and transmitted through the shaft into concrete.

Sizes:

- Head diameters range from 25 mm to 100 mm.

- Lengths vary from 1 to 6 meters, depending on shaft extension and depth requirements.

Applications:

- Foundation slabs

- Columns and walls

- Beams

- Precast molds

| Pros | Cons |

| √ High penetration depth | × Requires skilled operator to prevent over-vibration |

| √ Effective for medium to large concrete pours | × Not suitable for thin or delicate formwork |

| √ Portable and easy to handle |

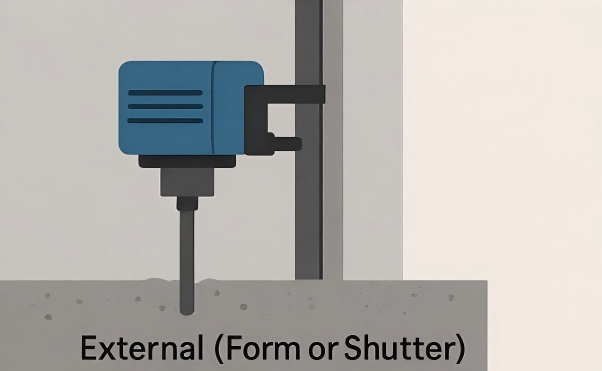

External (Form or Shutter) Vibrators

External vibrators are mounted to the exterior of concrete forms, typically on steel or wood shuttering. They vibrate the entire formwork to consolidate the concrete indirectly.

Working Principle:

They transmit vibration through the mold, causing the concrete to settle within the form due to uniform vibration of the formwork itself.

Applications:

- Precast concrete products (pipes, beams, panels)

- Complex or narrow forms

- Situations where internal vibrators can’t be used

| Pros | Cons |

| √ No need to insert into concrete | × Requires secure mounting |

| √ Suitable for precast and high-detail surface finishes | × Less effective for deep concrete pours |

| √ Reduced risk of concrete segregation | × Higher cost for large-scale projects |

Surface Vibrators (Screed Vibrators)

Surface vibrators sit on top of the poured concrete and vibrate the surface layer, typically used in finishing operations.

Types:

- Vibrating screeds

- Pan vibrators

- Plate vibrators

Working Principle:

They vibrate the concrete from above, pushing excess water to the surface and helping level the material while consolidating the top few inches.

Applications:

- Pavements and floors

- Road construction

- Thin slabs (up to 150 mm)

| Pros | Cons |

| √ Fast surface finishing | × Limited vibration depth (not for deep pours) |

| √ Useful for horizontal applications | × May not eliminate internal air pockets |

| √ Easy to operate |

Vibrating Tables

Vibrating tables are stationary platforms that vibrate precast concrete molds placed on top.

Working Principle:

The table vibrates to consolidate the concrete inside molds, ensuring air bubbles rise to the surface and forms are completely filled.

Applications:

- Precast concrete production

- Laboratory testing

- Decorative concrete parts (pavers, tiles, garden furniture)

| Pros | Cons |

| √ Excellent finish and compaction | × Fixed location (not mobile) |

| √ Ideal for controlled environments | × Requires power and space |

| √ High precision | × Slower for high-volume outdoor work |

Power Sources and Drive Mechanisms

Concrete vibrators can also be categorized by their power source:

| Power Source | Used In | Notes |

| Electric | Indoor, urban construction | Clean and quiet |

| Gasoline | Outdoor, remote sites | Portable but louder |

| Pneumatic | Explosive or wet environments | Used in tunnels or plants |

| Battery-powered | Portable worksites | Convenient, cordless |

Drive types:

- High-Frequency Vibrators: Operate above 9,000 rpm; fast and efficient

- Low-Frequency Vibrators: More affordable, used in general projects

Choosing the Right Type of Concrete Vibrator Made Simple

| Criteria | Recommended Type |

| Deep pours (>500 mm) | Internal (Needle) Vibrator |

| Thin slabs (<150 mm) | Surface Vibrator |

| Precast concrete production | External or Vibrating Table |

| Detailed molds | External Vibrator or Table |

| Power constraints | Pneumatic or Fuel-powered types |

| High-speed finishing | Vibrating Screed |

Common Mistakes When Using Concrete Vibrators

Even top equipment fails if used improperly. Avoid these common errors:

- Over-vibration: Can cause segregation and weakening

- Under-vibration: Leads to honeycombing and air pockets

- Wrong vibrator type: Reduces effectiveness or damages formwork

- Using damaged equipment: Reduces vibration force and coverage

- Improper insertion: Rapid insertion/removal reduces efficiency

- Inconsistent spacing: Uneven compaction across the pour

Innovations and Smart Features in Modern Concrete Vibrators

As a concrete vibrator manufacturer, integrating modern technology into your machines can enhance usability and performance:

- Variable frequency control: Adapts vibration strength for different mixes

- Remote control systems: Enhancing operator safety and convenience.

- Digital monitoring: Track vibration time, frequency, and runtime data

- Noise and vibration dampening: Improves ergonomics

- Battery-powered options: For emission-free use in closed spaces

Maintenance Tips for Concrete Vibrators

To ensure long service life and reliability, regular maintenance is key:

- Inspect head and shaft for wear

- Clean equipment after each use

- Lubricate moving parts as required

- Check for loose wiring or hose leaks

- Replace worn bearings or motors early

Industry Use Cases

Road and Highway Construction

Surface vibrators and needle vibrators are used extensively to compact slabs and road bases.

High-Rise Construction

Internal vibrators are used for columns, beams, and core walls due to their portability.

Precast Factories

External vibrators and vibrating tables ensure perfect finish in pipes, panels, and decorative parts.

Infrastructure and Bridges

Deep pours and complex forms require a combination of internal and external vibrators.

Global Market Trends for Concrete Vibrators

The global demand for concrete vibrators is growing due to urban infrastructure expansion, rising real estate, and industrial projects. Key trends include:

- Preference for cordless or battery-powered vibrators

- Growing use of high-frequency electric models

- Demand for customizable sizes and modular shafts

- Focus on durability and reduced maintenance

Understanding the various types of concrete vibrators, their applications, and their limitations helps in choosing the right tool for the job. As a manufacturer, offering a complete range—including internal, external, surface, and table vibrators—ensures you can meet diverse project requirements, from small-scale construction to industrial precast operations.

Quality equipment, user training, and maintenance support also play a key role in customer satisfaction and long-term brand reputation. By investing in innovation and education, manufacturers can lead the future of concrete consolidation technology.