Concrete consolidation is critical in any construction project involving poured concrete. Without proper vibration during placement, concrete can trap air voids, develop weak points, and fail to meet the expected strength and durability.

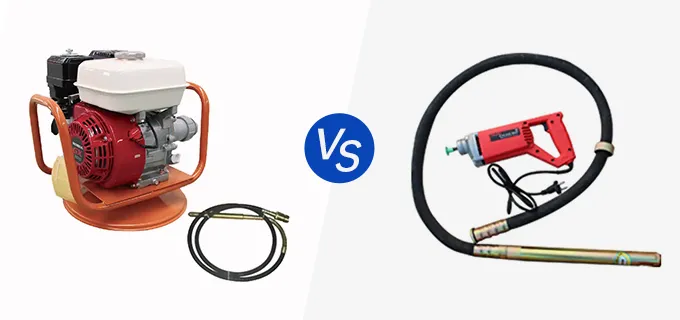

This is where internal concrete vibrators—also known as immersion vibrators—play a pivotal role. Among them, pencil vibrators and poker vibrators are widely used tools, each designed for specific applications and environments.

Understanding Internal Concrete Vibrators

Before comparing pencil and poker vibrators, it’s essential to understand the role of internal vibrators. These devices are placed directly into newly poured concrete. The head of the vibrator emits rapid vibrations that cause the concrete particles to realign and settle into a denser, more compact form. This process eliminates trapped air bubbles and ensures the concrete completely fills the mold or formwork.

Internal concrete vibrators are generally divided into two types:

- Pencil Vibrators (also known as needle vibrators or mini vibrators)

- Poker Vibrators (commonly referred to as standard immersion vibrators)

What is a Poker Vibrator?

A poker vibrator, also known as a needle vibrator or immersion vibrator, consists of a long cylindrical probe (the poker), a flexible shaft, and a motor unit (electric, pneumatic, or petrol-driven). The probe is inserted into fresh concrete, where it vibrates at high frequency and amplitude to remove entrapped air and consolidate the mix.

Key Features:

- Larger head diameter: Common sizes range from 25 mm to 75 mm or more.

- Robust construction: Often used with electric motors or gasoline engines.

- Medium to high frequency: Usually around 6,000 to 12,000 vpm.

- Higher amplitude: Enables deeper and broader vibration coverage.

Typical Applications:

- Foundations and slabs

- Columns and walls

- Road and bridge construction

- Large precast elements

- Dams and industrial concrete pours

Typical sizes and performance:

| Parameter | Value Range |

| Poker diameter | 25 mm – 75 mm |

| Frequency | 6,000 – 12,000 vibrations/min |

| Amplitude | 1 – 3 mm |

| Power source | Electric, diesel, pneumatic |

| Typical application | Medium to large pours |

What is a Pencil Vibrator?

A pencil vibrator is a specialized form of internal vibrator with a small-diameter head, typically between 5 mm and 15 mm. It is designed for use in narrow, confined, or reinforced concrete spaces where standard poker vibrators cannot reach without disturbing the rebar or formwork.

Key Features:

- Small diameter head: Usually ranges from 10 mm to 25 mm.

- Flexible shaft: Allows access into tight corners or dense rebar meshes.

- High frequency: Often vibrates at 12,000 to 18,000 vibrations per minute (vpm).

- Lower amplitude: Designed for precision rather than bulk consolidation.

Typical Applications:

- Precast concrete elements

- Thin concrete layers (e.g., walls, beams)

- Decorative or architectural concrete

- Reinforced concrete with tightly spaced rebar

- Laboratory testing of concrete samples

Typical sizes and performance:

| Parameter | Value Range |

| Pencil diameter | 5 mm – 15 mm |

| Frequency | 10,000 – 20,000 vibrations/min |

| Amplitude | 0.3 – 1 mm |

| Power source | High-speed electric motor |

| Typical application | Precast forms, tight rebar areas |

Detailed Comparison Table: Pencil vs. Poker Vibrators

| Feature | Pencil Vibrator | Poker Vibrator |

| Head Diameter | 10 – 25 mm | 25 – 75 mm or larger |

| Vibration Frequency | High (12,000–18,000 vpm) | Medium (6,000–12,000 vpm) |

| Amplitude | Low | High |

| Reach & Flexibility | Very flexible for tight spaces | Less flexible but covers larger areas |

| Power Source | Electric (corded or battery) | Electric, gasoline, pneumatic |

| Primary Use | Delicate or reinforced concrete work | Mass concrete placement |

| Cost | Lower | Higher |

| Durability | Less robust | Designed for rugged use |

| Vibration Radius | Small (~50–100 mm) | Large (~200–450 mm) |

Application Scenarios

When to Use Poker Vibrators

Poker vibrators are ideal for:

- Large structural pours (e.g., foundations, bridges)

- Medium to high-slump concrete

- Removing large voids and honeycombing

- General site use, especially with wide spacing between rebars

Examples:

- Foundation pads

- Structural columns and beams

- Floor slabs and retaining walls

When to Use Pencil Vibrators

Pencil vibrators are preferred when:

- Working with precast concrete elements

- Dealing with heavily reinforced or congested zones

- Filling tight mold areas without displacing rebar

- High aesthetic finishes are required (e.g., architectural concrete)

Examples:

- Precast staircase molds

- Rebar-dense columns and piles

- Concrete molds for sculptures and facade panels

Performance and Efficiency

| Criteria | Poker Vibrator | Pencil Vibrator |

| Compaction Depth | Deep, up to 50 cm per insertion | Shallow, around 15–20 cm |

| Area Coverage | Large | Small |

| Compaction Time | Faster in large volumes | Slower in precision areas |

| Risk of Over-Vibration | Higher (if misused) | Lower due to finer control |

| Operator Skill Needed | Moderate | High (to navigate rebar) |

Material Compatibility

While both vibrators are suitable for standard concrete mixes, their compatibility varies depending on slump, aggregate size, and form geometry.

| Concrete Condition | Best Fit |

| High slump, large volumes | Poker vibrator |

| Low slump, tight forms | Pencil vibrator |

| Lightweight concrete | Pencil vibrator (prevents segregation) |

| Exposed surface finish | Pencil vibrator (finer control) |

Equipment Durability and Maintenance

Poker Vibrators

- Maintenance: Requires regular shaft lubrication, checking for oil leaks, and probe wear.

- Durability: Designed for rugged use, usually reinforced housing.

- Challenges: Heavier; more moving parts mean more frequent maintenance.

Pencil Vibrators

- Maintenance: More sensitive; small internal components require careful handling.

- Durability: Built for precision, not extreme environments.

- Challenges: Prone to overheating if used continuously in thick concrete.

Cost and Budget Considerations

| Aspect | Poker Vibrator | Pencil Vibrator |

| Initial Equipment Cost | Higher due to larger motor and probe | Lower due to compact size |

| Operating Cost | Higher fuel/electricity usage | Lower power consumption |

| Maintenance Cost | Moderate to high | Low to moderate |

| Productivity (per hr) | Higher for large pours | Lower, but more precise |

| ROI (Return on Investment) | Fast for general works | Essential for specialized applications |

Choosing the Right Vibrator for Your Job

Questions to Consider

- What is the size and type of the pour?

- Are you working in tight, reinforced areas?

- Is surface finish critical to your structure?

- Do you require mobility or lightweight handling?

- What is your budget and expected ROI?

Recommendations

- For general-purpose, high-volume site work: Choose a poker vibrator.

- For detail work, thin molds, and aesthetics: Opt for a pencil vibrator.

- On large projects, it’s often best to use both types where needed.

Real-World Example

Imagine a construction crew tackling a high-rise building project. For pouring the large floor slabs and foundation base, they rely on poker vibrators due to the sheer volume of concrete. However, for the columns, especially those with dense reinforcement near the core, they use pencil vibrators to ensure the mix consolidates properly without damaging rebar or leaving voids.

This dual-approach maximizes both efficiency and precision, ultimately delivering a high-quality structure with strong compaction and minimal defects.

Safety Considerations

Both tools require proper training and handling:

- Avoid prolonged exposure to vibration (use anti-vibration gloves).

- Regularly inspect cables and flexible shafts.

- Never insert or remove the vibrator while it’s on.

- Avoid excessive vibration, as it can cause concrete segregation or bleeding.

Innovations in Vibrator Technology

Today, leading manufacturers offer:

- Battery-powered pencil vibrators for portability

- Variable-speed control for both vibrator types

- Noise reduction systems

- Wireless remote controls

- Smart sensors to monitor vibration time and frequency

These advancements reduce operator fatigue, increase productivity, and ensure consistent quality.

Choosing a reputable concrete equipment manufacturer ensures you receive:

- Quality-tested vibrators with robust motor housing and balanced vibration heads

- Custom options for shaft length, head size, and motor type

- Ongoing service support and guaranteed spare parts supply

- Adheres to ISO and CE certification requirements

As a manufacturer, we offer both pencil vibrators and poker vibrators, customizable to suit various construction needs. Whether you’re in precast production, bridge building, or high-rise construction, our solutions are built to perform with precision and durability.