Ride-on Power Trowel Manufacturer&Supplier

Our Ride-On Trowel Machine delivers unmatched speed and precision for large-scale concrete finishing.

Designed for operator comfort and productivity, it ensures superior flatness, smooth surfaces, and reduced labor time.

- Blade Quantity: 4/5*2

- Blade Speed: 140-170RPM

- Engine Type: Gasoline

- Work Diameter: 120cm-160cm

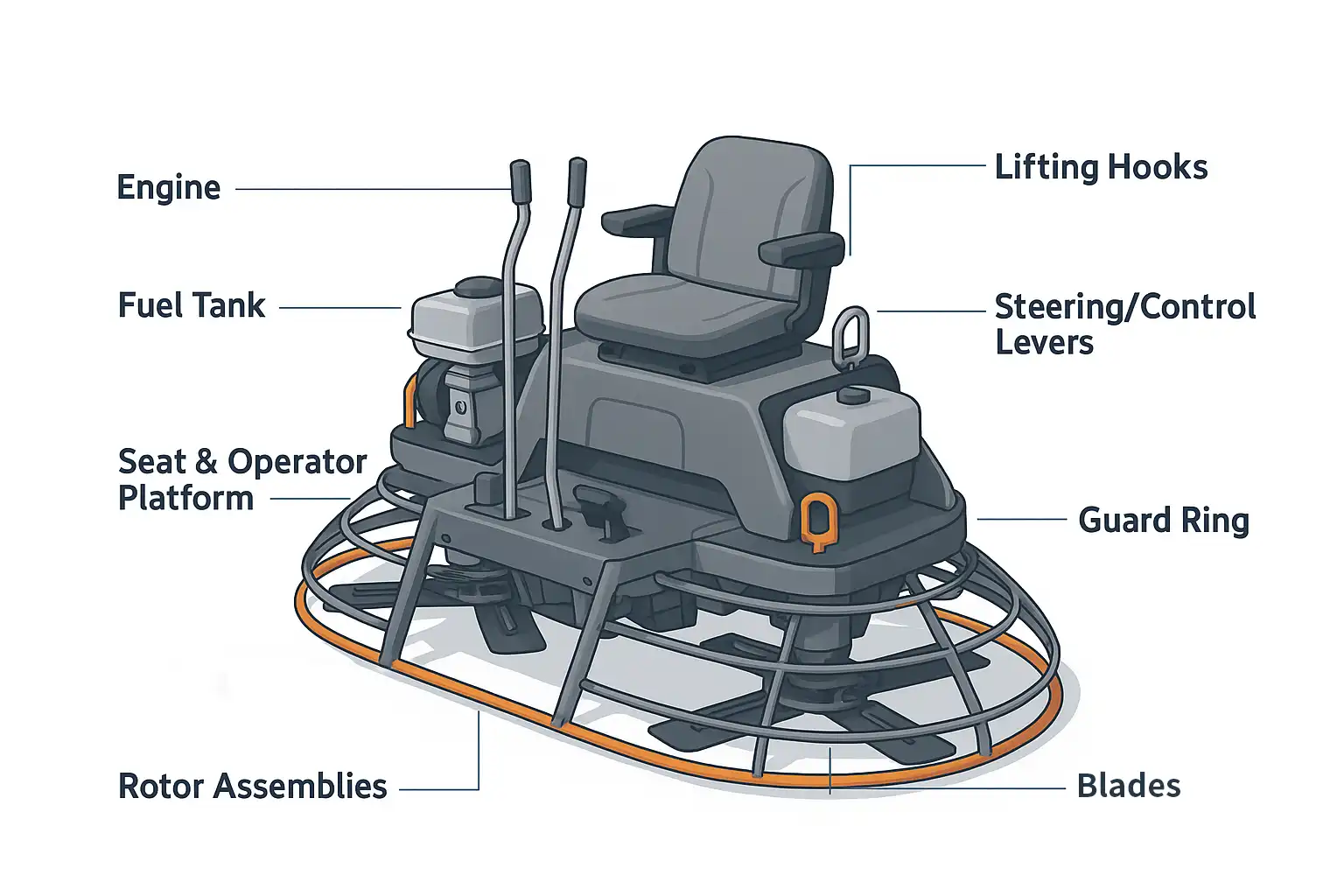

What are Components of Ride-on Power Trowel?

- Engine : Powers the machine (commonly gasoline or diesel).

- Gearbox: Transfers engine power to blade rotation.

- Blades : Do the actual finishing (float or finish blades).

- Rotor Assemblies: Hold and rotate the blades (usually two rotors).

- Seat & Operator Platform: Where the operator sits to control the machine.

- Steering/Control Levers: Used to maneuver and adjust blade pitch.

- Guard Ring: Safety feature around the blades.

- Fuel Tank : Supplies fuel to the engine.

- Lifting Hooks : For easy transport on-site.

- Lighting System (optional) : For night or low-light work.

What kind of Control System Can We Provide?

Mechanical Drive

- Uses belts, clutches, and gearboxes for blade rotation.

- Lower cost, more affordable upfront investment.

- Durable, simple construction with easy maintenance.

- Provides direct operator control with responsive handling.

Hydraulic Drive

- Uses hydraulic pumps and motors for blade rotation.

- Smooth, effortless steering with reduced operator fatigue.

- Precise control for large-scale concrete finishing.

- Fewer mechanical parts, less wear and tear.

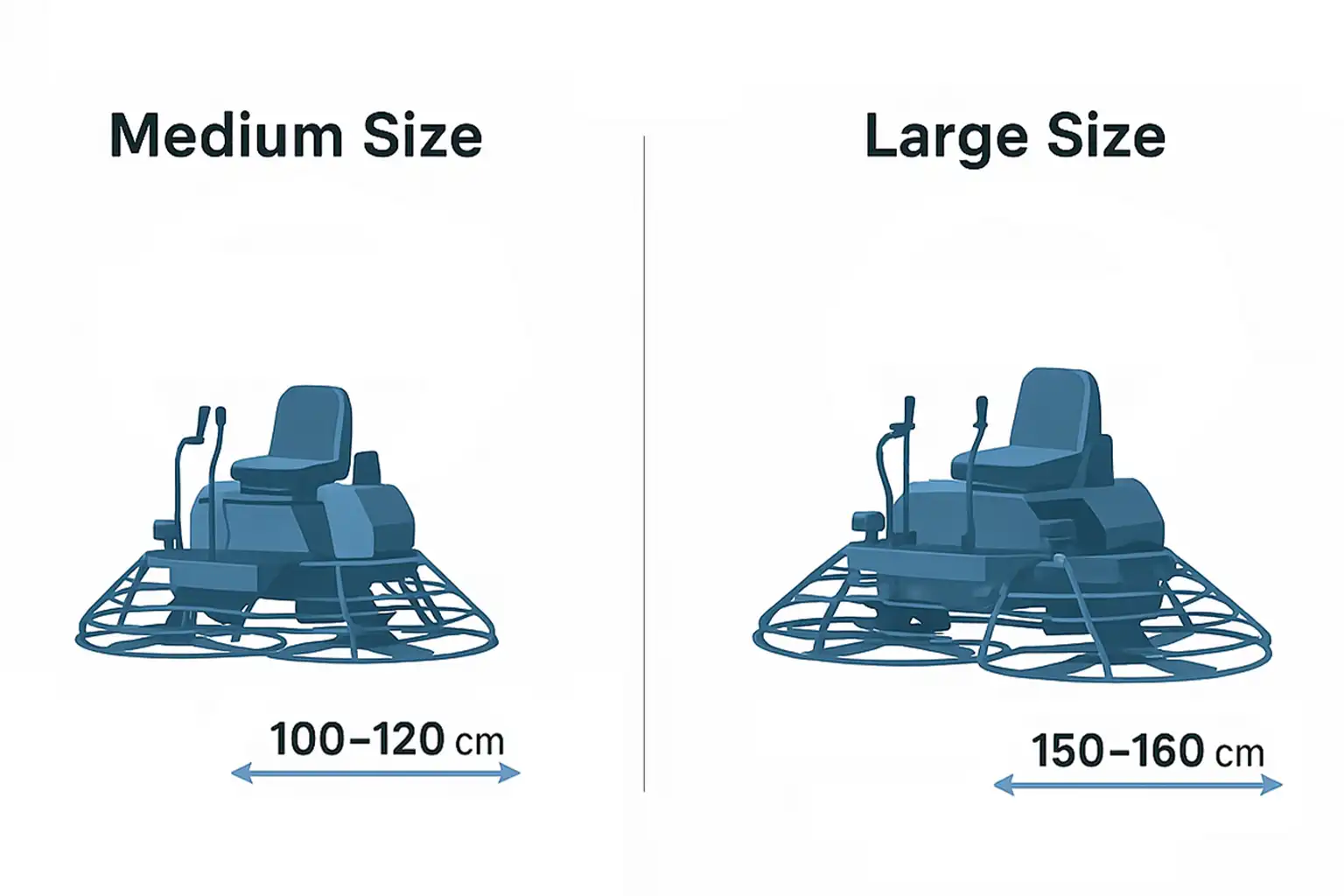

What Size of Ride on Trowel Can We Provide?

Ride-on trowel size is measured by working diameter; our models provide 120–150 cm coverage per rotor.

Medium Size(100–120 cm)

- Covers around 1.5–2.0 m² per pass, suitable for projects up to 500–1,500 m² in size.

- Offers an excellent compromise between wide surface finishing and ease of handling.

- Warehouses, airport runways, industrial floors, shopping malls.

Large Size(150–160 cm)

- Covers 2.5–3.0 m² per pass, suitable for projects above 1,500 m² where speed and surface flatness are critical.

- Covers significantly more area per pass, drastically reducing finishing time on expansive slabs.

- Warehouses, airport runways, industrial floors, shopping malls.

Featured Products

VS830 Concrete Ride-on Power Trowel

- Dimension (mm): 1600*850*1080

- Blade Speed: 150 rpm/min

- Engine: B&S XR2100

- Working Diameter: 1600mm

VS836 Concrete Ride-on Power Trowel

- Dimension(mm): 2000*1000*1350

- Blade Speed (max.): 150rpm ±10rpm

- Engine: HONDA GX690

- Engine Lubricating Oil: SAE30

VS1046 Concrete Ride-on Power Trowel

- Motor Type: BRIGGS & STRATTON

- Power: 34HP

- Start Mode: Electric Start

- Fuel Tank: 40L

Applications

Infrastructure Projects

- Widely applied in airports, highways, railway stations, and bridges.

- Large working diameter and powerful performance make it suitable for finishing expansive slabs in less time.

Sports and Event Facilities

- Applied in stadiums, gyms, and arenas where flat concrete floors are necessary for safe use and installation of finishes.

- Ensures a level base for further flooring materials such as epoxy, tiles, or wood.

Large Industrial Floors

- Ideal for warehouses, factories, and logistics centers requiring smooth, durable surfaces for machinery and vehicles.

- Provides consistent flatness that ensures durability and reduces maintenance costs over time.

FAQ

What sizes are available for ride-on trowels?

They usually come in medium size (≈100–120 cm) for maneuverability and large size (≈150–160 cm+) for expansive slabs like warehouses and airports.

Can one operator control a ride-on power trowel easily?

Yes. They are designed with ergonomic seats, intuitive controls, and in some models, hydraulic steering for better handling and comfort.

How many blades does a ride-on power trowel typically have?

Most dual-rotor ride-on trowels use 4–5 blades per rotor, while pan attachments are available for floating stages.

How should I maintain my ride-on power trowel?

Routine maintenance includes checking oil levels, inspecting belts, greasing bearings, cleaning blades/pans, and replacing worn parts as per the manufacturer’s schedule.

Can one ride-on trowel handle floating as well as finishing?

Yes. By changing pitch angles, blades, or attaching float pans, the same machine can handle both floating and finishing stages.