Walk Behind Trowel Machine

Engineered for flawless concrete finishing, our Walk Behind Power Trowel delivers unmatched smoothness, durability, and control.

Designed for precision and operator comfort, it delivers high productivity, easy maneuverability for contractors on any jobsite.

- 4 blade design

- 24 inch to 48 inch sizes available

- Mechanical boom swings 180° laterally

- Gasoline and electric power options available

- One-year warranty

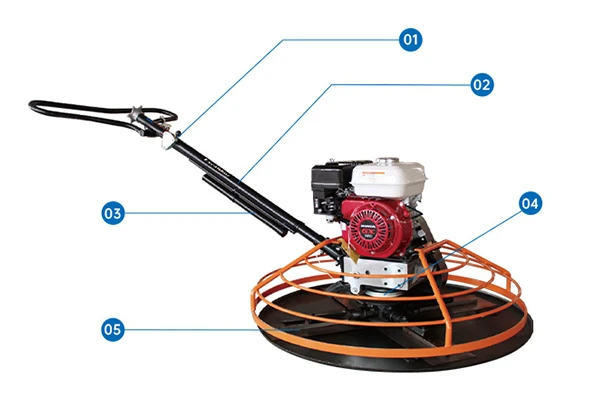

Components of Walk Behind Trowel

- 1.Height-adjustable handle provides comfortable control for every operator.

- 2.Ergonomic handle design ensures easy access from the driving position.

- 3.Convenient lifting hook allows simple transport and handling.

- 4.Durable cast aluminum gearbox delivers reliable performance.

- 5.Safety-focused guard ring enhances operator protection during operation.

What is the Engine Power of Our Walk Behind Trowel?

Gasoline Engine

- ROBIN EY20, HONDA GX160, LIFAN200F

- 87–93 octane unleaded

- High power output, suitable for heavy-duty finishing

- More portable—no need for cords or external power

- Roads, bridges, warehouses, large outdoor projects

Electric Motor

- 220V–380V AC

- Continuous, as long as power supply is available

- Quieter operation(70–80 dB)

- Lower operating costs

- Basements, tunnels, factories, enclosed construction projects

Our Walk Behind Concrete Trowel Size Option

24-36in(Diameter: 600–800 mm)

- Easy to operate in tight spaces or near edges.

- Suitable for small slabs, residential floors, sidewalks, and repair jobs.

- Reduces operator fatigue and allows simple transport.

- Contractors needing fine finishing in restricted or irregularly shaped areas.

46-48in (Diameter: 1000-1200mm)

- Covers wide areas quickly, saving labor time.

- Ideal for industrial slabs, warehouses, and large construction projects.

- Typically equipped with stronger engines for extended use.

- Large-scale contractors prioritizing speed and surface uniformity.

What Can Our Machines be Customized?

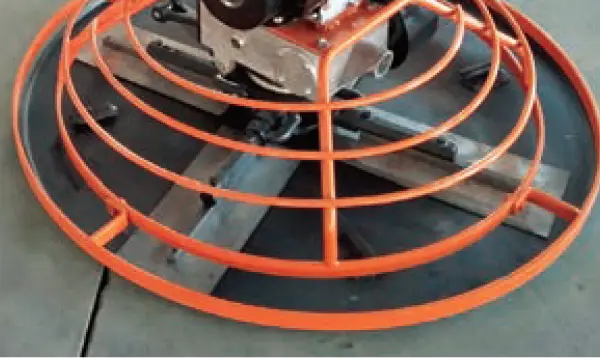

Guard Ring

- We offer different guard ring designs to enhance both safety and durability.

- Choose standard guard rings for general use or reinforced ones for demanding jobsites.

Handle Type

- Handles can be customized to meet operator preferences and jobsite demands.

- Choose fixed, height-adjustable ergonomic, or vibration-dampened handles for comfort, control.

Color

- Machines painted in custom colors to match branding, style, and project needs.

- Powder-coated finish improves appearance while protecting the machine from rust.

Featured Product

Model | ST-24 | ST-30 | ST-36 | ST-48 |

Trowel Diameter(mm) | 600 | 800 | 1000 | 1200 |

Number of Blades | 4 | 4 | 4 | 4 |

Driving Speed(rpm) | 50-100 | 50-100 | 50-130 | 70-145 |

Blade Dimension(mm) | 220*130 | 265*150 | 350*150 | 405*150 |

Packing Size(L*W*H)mm | 600*600*660 | 1000*1000*660 | 1000*1000*660 | 1200*1200*880 |

Net Weight (KG) | 60 | 75 | 75 | 80 |

Engine Model | ROBIN EY20 | ROBIN EY20 | ROBIN EY20 | HONDA GX270 |

Applications

Residential Construction

- Used for finishing house floors, patios, driveways, and garages.

- Designed compactly for smooth operation around walls, edges, and confined areas.

Commercial Projects

- Suitable for shops, office floors, small warehouses, and retail spaces.

- Ensures flat, high-quality finishes required for commercial flooring durability.

Small Industrial and Infrastructure Works

- Commonly used in parking lots, walkways, pavements, and small factory floors.

- Ensures long-lasting surfaces that can handle heavy foot and light vehicle traffic.

Walk Behind Trowel Machine Installation Steps

- Two 17 mm wrenches

- One 13 mm wrench

- One 12 mm wrench

- One 10 mm wrench

- One 8 mm wrench

- One Phillips screwdriver

- Insert the handle tube into the handle mounting pipe.

- Align the four holes vertically, top to bottom.

- Pass bolts through aligned holes.

- Add flat and spring washers at the bolt’s lower end.

- Place a lock nut on the bolt head.

- Tighten securely with two 17 mm wrenches.

- Insert the pin into hole securely.

- Pass the top screw of the steel cable through the pin hole.

- Place a nut on the protruding screw.

- Make sure this step is completed before starting the machine, otherwise it may affect the gearbox operation.

FAQ

How do I start and operate a walk-behind trowel machine?

Fill with fuel (or connect to power for electric models), start the engine, adjust blade pitch, and guide it slowly over the concrete surface.

When can I use a trowel machine on fresh concrete?

Begin once the concrete is firm enough to support the operator’s weight without leaving deep footprints but still plastic for finishing.

Are there different sizes available?

Yes. Walk-behind trowels typically range from 24” to 48” in working diameter to suit different project sizes.

How often should I service my machine?

Check oil, air filter, and belts daily. Perform full servicing (oil change, blade replacement, inspection) after every 50–100 hours of use.

How long do blades last?

Blade life depends on use, concrete abrasiveness, and maintenance. On average, 30–60 hours of continuous work before replacement is recommended.