In concrete finishing, achieving a smooth, polished, and durable surface requires more than just a quality mix and timely pour. It demands precision in the final stage—troweling. As a professional manufacturer of power trowels, we know that two of the most critical variables in the finishing process are blade angle and rotor speed.

Get them wrong, and you risk poor surface quality, structural weakness, or costly rework. Get them right, and you’ll deliver a flawless floor with long-lasting performance.

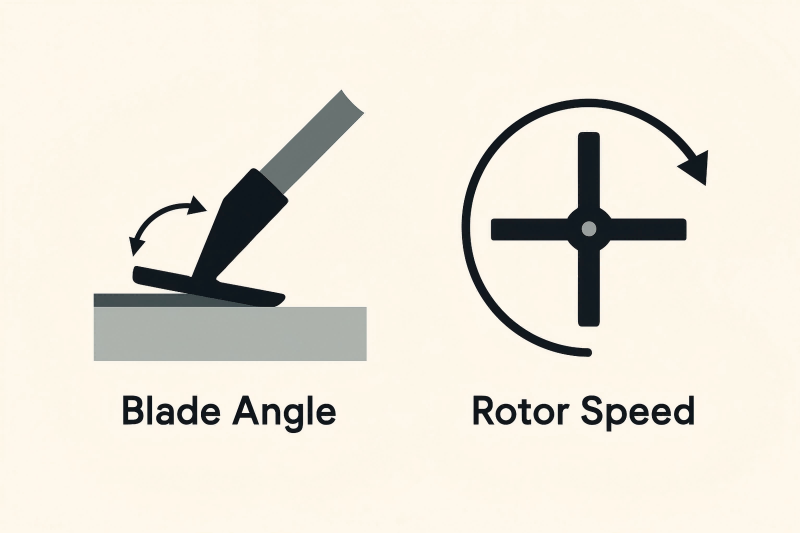

Blade Angle and Rotor Speed

Before discussing optimization strategies, let’s define the two components at the heart of power troweling efficiency:

Blade Angle (Pitch)

The blade angle, often referred to as the pitch, refers to the tilt of the blades in relation to the surface. A flat blade has zero pitch, while an angled blade applies pressure to the concrete.

- Flat (0°–5°): Used for floating—initial passes where concrete is still plastic.

- Moderate (5°–10°): Intermediate phase, blending float and finish.

- Steep (10°–20°): Used for finishing—closing the surface and polishing it.

Rotor Speed (RPM)

Rotor speed refers to the revolutions per minute of the trowel’s rotor assembly. It determines how quickly the blades pass over the surface.

- Low speed (50–90 RPM): Used during floating to avoid disturbing the surface.

- High speed (100–150+ RPM): Used during finishing to burnish and compact.

Blade pitch and speed must be adjusted dynamically during the job to suit the concrete’s setting time and the finish desired.

Why Blade Angle Matters

Correct blade pitch ensures efficient contact with the slab. A common mistake is using too much pitch too early or too little pitch during finishing.

Effects of Improper Blade Angle

| Mistake | Impact on Surface |

| Too flat during finishing | Weak, powdery, or porous surface |

| Too steep during floating | Gouging, tearing, and pushing aggregate |

| Inconsistent angle use | Uneven sheen or wave patterns in the floor |

Why Rotor Speed Matters

Rotor speed affects how much force is applied and how frequently the surface is worked. Faster speeds increase blade contact, heat, and surface closure, but they must be used wisely.

Effects of Incorrect Speed

| Rotor Speed Issue | Resulting Problem |

| Too fast too early | Tears up surface, reduces flatness |

| Too slow during finishing | Inadequate compaction, reduced shine |

| Speed not matched to pitch | Inconsistent finish or visible blade marks |

Stages of Concrete Finishing and Ideal Settings

Power troweling typically goes through multiple passes. Each pass corresponds to a different phase of slab curing, and the blade angle and rotor speed should evolve accordingly.

Floating Stage

- Timing: When concrete is firm enough to support the trowel but still wet inside

- Purpose: Flatten surface, embed aggregate, remove imperfections

- Blade Angle: 0°–5° (flat)

- Rotor Speed: Low (60–90 RPM)

Use float pans or combination blades. Keep pitch minimal to avoid digging in. This pass ensures the surface is level and prepared for a smooth finish later.

Intermediate Stage

- Timing: Concrete is firmer; water sheen has disappeared

- Purpose: Begin surface closing

- Blade Angle: 5°–10°

- Rotor Speed: Medium (90–110 RPM)

Switch to combination or finish blades. The slight angle helps compress and close the surface without causing damage.

Finishing Stage

- Timing: Surface is hard but still workable

- Purpose: Polish, densify, and seal surface

- Blade Angle: 10°–20°

- Rotor Speed: High (110–150+ RPM)

At this stage, switch to finish blades. Increase both speed and pitch gradually for maximum polish. Be careful not to over-burnish, especially if applying coatings later.

Adjusting Blade Pitch: Manual vs. Mechanical Systems

Modern power trowels offer various pitch control mechanisms:

Manual Pitch Control (Walk-Behind)

- Operator adjusts each blade individually using a knob or handle

- Best for smaller jobs where conditions vary less

Mechanical/Hydraulic Pitch Control (Ride-On)

- Centralized adjustment from control panel

- Ideal for large commercial floors

- Allows dynamic changes without stopping the machine

Regardless of system, operators must understand how and when to make adjustments based on visual and tactile cues.

Tips for Optimizing Blade Angle and Speed

To achieve professional-level finishes, follow these manufacturer-recommended best practices:

Tip 1: Conduct a Slab Test

Before committing to full troweling, test a small area with different pitch and speed combinations. Evaluate the gloss, smoothness, and material response.

Tip 2: Adjust Based on Conditions

Hot, dry weather may require faster transitions through passes, while cool, humid weather offers more time. Always match blade angle and speed to slab condition.

Tip 3: Don’t Max Out Too Early

High pitch and high RPM too early can seal the surface prematurely, trapping moisture and causing future cracking.

Tip 4: Use Consistent Overlap

Maintain a 20–30% overlap between passes. Uniform movement avoids missed spots and inconsistent sheen.

Tip 5: Train Your Operators

Even experienced finishers may have different preferences. Standardize training on your specific trowel models to ensure consistency in angle, speed, and technique.

Common Mistakes to Avoid

| Mistake | Why It’s a Problem |

| Starting with high pitch and speed | Damages surface, causes delamination |

| Not adjusting pitch between passes | Results in poor compaction or uneven finish |

| Relying on a single setting for the whole job | Concrete evolves; settings must too |

| Ignoring weather effects | Can lead to rushed or delayed troweling |

| Not inspecting blades regularly | Worn blades affect performance and increase workload |

Tools to Help With Blade and Speed Control

Modern power trowels often include features that simplify angle and speed adjustments:

- Digital RPM gauges: For precise speed monitoring

- Pitch indicators: Show current blade angle on a dial

- Variable-speed controls: Let you fine-tune RPM during operation

- Ergonomic handlebars or joysticks: Improve comfort and control during adjustment

If your machine doesn’t have these features, consider aftermarket accessories or upgrading to a newer model with enhanced control options.

Matching Blade Settings to Surface Type

Not all concrete surfaces require the same finish. Blade settings can be customized depending on end use:

| Application | Recommended Finish | Blade Angle | Rotor Speed |

| Warehouse floors | High gloss | 15°–20° | 120–150+ RPM |

| Exterior slabs | Light polish (non-slip) | 5°–10° | 90–110 RPM |

| Decorative concrete | Smooth, coating-ready | 10°–15° | 110–130 RPM |

| Industrial base slabs | Medium hard, no glaze | 8°–12° | 100–120 RPM |

Maintenance Tips for Consistent Blade Performance

A blade is only as good as its condition. Keep your blades in peak shape:

- Inspect before each job: Check for cracks, warping, or uneven wear

- Replace damaged blades promptly

- Clean blades after every use

- Keep in a dry place to avoid rusting.

- Follow manufacturer guidelines for sharpening or replacement.

A dull or uneven blade won’t respond correctly to pitch or speed adjustments, leading to poor finishing outcomes.

Achieving the perfect concrete finish requires more than simply turning on your power trowel and walking it across the slab. Understanding and adjusting blade angle and speed settings throughout the job is essential to delivering professional-grade results. These two factors work together to balance surface pressure, compaction, and polish.

As a power trowel manufacturer, we strongly recommend that users develop a keen awareness of the changing concrete conditions, use the appropriate tools for control, and follow a strategic approach to blade pitch and rotor speed at each stage. Whether you’re smoothing a warehouse floor, a decorative patio, or an industrial foundation, mastering these settings ensures durability, aesthetics, and long-term performance.

For more support or to explore power trowels designed with advanced pitch and speed control, contact our team.