Concrete scarifiers, or surface planers, are essential tools for construction and surface preparation tasks. Used for leveling, texturing, grooving, or removing coatings from concrete surfaces, these machines rely on rotating assemblies packed with cutting tools to deliver high-impact abrasion.

At the heart of every scarifier lies one of two key components: cage assemblies or drum assemblies. While they perform similar functions—rotating cutters to remove concrete—they differ significantly in design, performance, maintenance, and application. Understanding the differences is crucial for contractors, rental companies, and project managers seeking optimal efficiency, durability, and results.

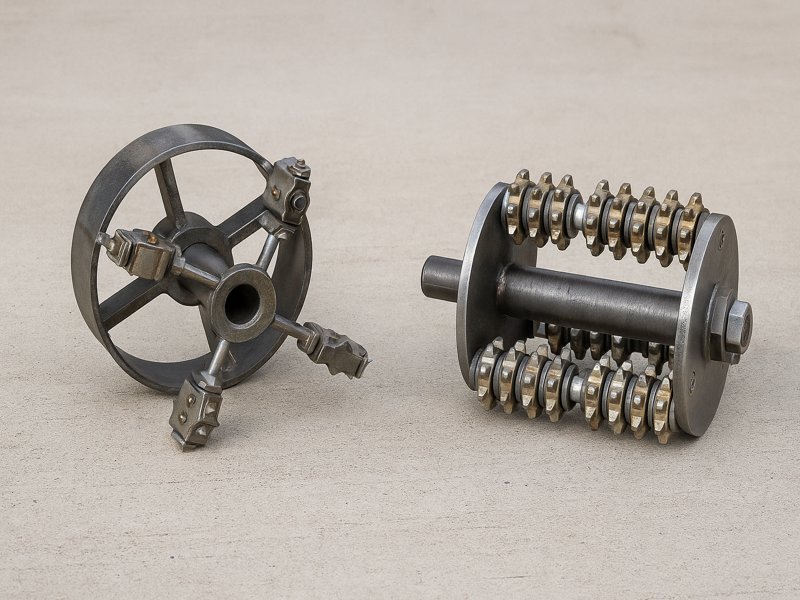

What Is a Cage Assembly in a Scarifier?

A cage assembly consists of a steel cage-like frame that holds and spins various flail or rotary cutters. The cutters are mounted on shafts or spindles that rotate freely within the cage when the machine operates.

Structure:

- Open cylindrical cage

- Multiple flails mounted on spindles

- Used mostly in lighter-duty or rotary-action scarifiers

Cutter Types Used:

- Tungsten carbide flails

- Star cutters

- Beam cutters

Key Characteristics:

- More flexible and lightweight

- Suitable for thin coatings, light concrete removal, and surface cleaning

- Easier and faster to change cutters

| Pros | Cons |

| √ Lightweight and easy to handle | × Less aggressive |

| √ Quick cutter changes | × Less consistent cut depth |

| √ Lower initial cost | × Wears out faster |

| √ Ideal for flexible, low-depth jobs |

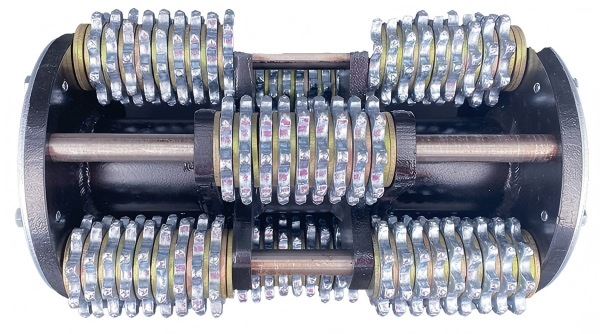

What Is a Drum Assembly in a Scarifier?

A drum assembly is a solid cylindrical drum that houses rows of cutting shafts or flails. The cutters are bolted or mounted directly on the drum, which is rotated by the machine’s motor at high RPMs. The rigid nature of the drum allows for deeper, more aggressive cutting action.

Structure:

- Solid steel drum (like a cylinder)

- Heavier and more robust than cages

- Precisely aligned rows of flails or cutters

Cutter Types Used:

- Tungsten carbide cutters

- Milling wheels

- Wire brushes (for light duty)

Key Characteristics:

- Heavier, more aggressive cutting

- Ideal for industrial use, floor leveling, heavy coating removal

- Offers precision and depth consistency

| Pros | Cons |

| √ Aggressive and fast-cutting | × Heavier and harder to transport |

| √ Long tool life with proper maintenance | × Costlier upfront |

| √ Precise depth and finish control | × More complex maintenance |

| Suitable for large commercial jobs |

Key Differences Between Cage and Drum Assemblies

| Feature | Cage Assembly | Drum Assembly |

| Structure | Lightweight, cage-like frame | Solid cylindrical steel drum |

| Weight | Lighter | Heavier |

| Cutting Action | Freely rotating cutters (flails) | Rigid, fixed-cutting paths |

| Aggressiveness | Low to medium | Medium to high |

| Material Removal Rate | Lower, less aggressive | Higher, more aggressive |

| Ideal Applications | Surface cleaning, light coating removal | Deep concrete milling, trip hazard removal |

| Precision | Less consistent depth | Very consistent depth and cut profile |

| Tool Change Time | Faster, simple replacement | Longer, more involved |

| Cost | Lower upfront cost | Higher cost but longer life |

| Durability | Wears faster, frequent maintenance | Robust, longer lifespan |

| Machine Types | Light-duty rotary scarifiers | Heavy-duty walk-behind/ride-on scarifiers |

Comparative Performance Metrics

To help visualize how these assemblies perform in real-world applications, let’s look at some quantitative performance data:

| Metric | Cage Assembly | Drum Assembly |

| Average Removal Rate | 150–250 ft²/hr | 300–450 ft²/hr |

| Cutting Depth per Pass | 1–3 mm | 3–6 mm |

| Surface Profile (CSP Rating) | CSP 2–4 | CSP 4–9 |

| Tool Life (avg) | 6–8 hours | 3–5 hours |

| Noise Level | ~85 dB | ~100 dB |

| Vibration Level | Lower (due to flail absorption) | Higher (direct impact) |

| Initial Cost | Lower | Higher |

| Best for | Paint, adhesives, sealers | Concrete milling, epoxy removal |

Applications: Where Each Assembly Excels

Cage Assembly Applications:

- Removing thin paint, adhesives, or epoxies

- Texturing walkways for slip resistance

- Cleaning off oil stains or light grime

- Preparing surfaces for overlays

- Indoor residential or decorative concrete work

Why choose it: When mobility, cost, and surface gentleness matter more than cutting depth or volume.

Drum Assembly Applications:

- Removing 3–5 mm thick coatings

- Leveling uneven concrete slabs

- Eliminating sidewalk trip hazards

- Removing thermoplastics and traffic lines

- Industrial floor rehabilitation

- Airport runway grooving

Why choose it: When consistency, depth control, and production rate are critical.

| Application | Recommended Assembly |

| Paint removal | Cage |

| Coating/adhesive removal | Cage |

| Line striping removal | Drum |

| Grooving/texture creation | Drum |

| Concrete leveling | Drum |

| Epoxy or overlay removal | Drum |

| Decorative surface prep | Cage |

| Tile mastic/glue cleanup | Cage |

| Bridge deck prep | Drum |

Performance Metrics: Speed, Depth, and Power

Removal Depth:

- Cage Assembly: 1–2 mm per pass (typical)

- Drum Assembly: 3–6 mm per pass (typical, depending on cutter type)

Removal Rate:

- Cage: Up to 60 m²/hour (light applications)

- Drum: Up to 100 m²/hour (heavy-duty removal)

Power Compatibility:

- Cage-based machines: 1–5 HP (light-duty models)

- Drum-based machines: 5–25 HP+ (industrial grade)

Maintenance Considerations

Cage Assembly Maintenance:

- Regular replacement of flails

- Bearing lubrication

- Easy disassembly for routine inspection

- Faster wear due to open structure

Drum Assembly Maintenance:

- Cutter replacement more labor-intensive

- Requires alignment checks for balance

- Less frequent, but longer service time

- Heavy to lift and requires trained technicians

Cost Considerations

Initial Cost:

- Cage assemblies are typically 15–30% cheaper than drum assemblies.

- Ideal for small contractors or one-time projects.

Long-Term Cost:

- Cage assemblies may need more frequent replacements.

- Drum assemblies cost more but last longer with proper maintenance.

Choosing the Right Assembly: Factors to Consider

- Project Scale: Use drum assemblies for large, industrial projects. For quick residential or small business work, cage assemblies work fine.

- Desired Surface Finish: Drum assemblies produce smoother and more even finishes due to consistent depth. Cage assemblies may leave uneven textures.

- Budget: Cage assemblies are budget-friendly for occasional use. Drum assemblies are a better long-term investment for contractors with frequent, heavy use.

- Operator Skill: Cage-based machines are easier for beginners to handle, while drum machines require trained operators for safety and precision.

- Equipment Availability: If you already own a machine, check if it’s compatible with both types—some allow interchangeable heads.

Hybrid Solutions: Convertible Scarifiers

Some modern scarifier machines support interchangeable assemblies. Users can swap between cage and drum systems based on job requirements. These hybrid systems provide flexibility and cost-efficiency—especially valuable for rental companies and contractors serving a wide client base.

Safety Tips for Using Either Assembly

Always inspect assemblies before use for wear and damage.

Wear personal protective equipment (PPE): goggles, ear protection, gloves, and dust masks.

Never adjust assemblies while the machine is running.

Ensure proper dust collection or vacuum connection to minimize silica exposure.