Concrete finishing is a critical step in construction, especially for flooring projects in commercial, industrial, and residential settings. Achieving a smooth, level, and durable concrete surface requires precision and the right equipment—and that’s where power trowels come in.

What Is a Power Trowel?

Unlike manual trowels, it’s designed for large surface areas, delivering a uniform, polished finish quickly. Powered by gas, diesel, electricity, or batteries, it features rotating blades that compact and smooth wet concrete efficiently.

Basic Mechanism of Power Trowels

To understand how a power trowel works, it’s helpful to look at its core components and how they interact.

Key Components

| Component | Function |

| Engine | Powers the rotating blades |

| Gearbox | Transfers energy from the engine to the blade system |

| Blades/Pans | Smooth and finish the concrete |

| Handle/Control | Allows operator to steer and control rotation |

| Guard Ring | Ensures safety by enclosing spinning blades |

Working Principle

The engine drives the blades through a gearbox. These blades rotate horizontally over the surface of freshly poured and partially set concrete. As they spin, they apply downward pressure, which compacts the concrete and helps it cure into a flat, dense surface.

There are two types of blade setups:

- Float blades: Used initially to level and compact wet concrete.

- Finish blades: Used later to create a smooth and polished surface.

Some machines use a trowel pan instead of blades during the floating stage. The pan is a large disc that helps distribute weight more evenly and prevents blade marks during the early stages of finishing.

Types of Power Trowels

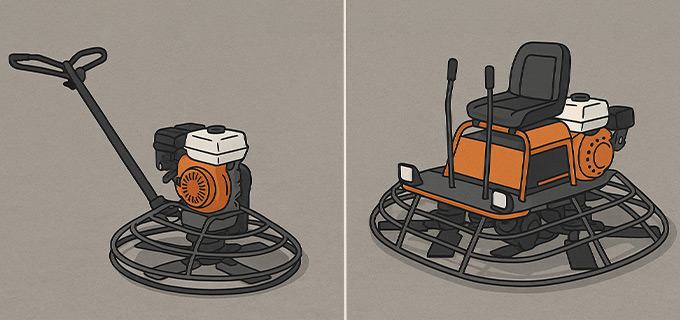

There are two main categories of power trowels: walk-behind and ride-on. Each option has advantages, disadvantages, and specific applications where it performs best.

Walk-Behind Power Trowels

These are single-operator machines pushed from behind, much like a lawnmower.

Key Features:

- Blade sizes typically range from 24″ to 48″

- Used for small to medium-sized slabs

- Affordable and easy to transport

- Manual control through handles

| Pros | Cons |

| √ Lower cost | × Physically demanding |

| √ Ideal for small contractors or tight spaces | × Slower for large projects |

| √ More control for detailed work |

Best Used For:

- Residential floors

- Small commercial areas

- Garage floors, sidewalks, and patios

Ride-On Power Trowels

These let the operator ride the machine and steer it using joysticks or levers.

Key Features:

- Twin rotors with overlapping or non-overlapping blades

- Larger surface coverage—up to 12 feet in one pass

- Powered by gasoline, diesel, or propane

| Pros | Cons |

| √ Faster operation | × More expensive |

| √ Covers large areas efficiently | × Harder to operate in confined areas |

| √ Less physical strain on the operator | × Requires skilled operators |

Best Used For:

- Warehouses

- Airports

- Shopping malls

- Large commercial/industrial slabs

Blade and Pan Options

Understanding the blade system is crucial to mastering power trowel operation.

Types of Blades

| Blade Type | Description | Use |

| Float Blade | Wider, rounded edges | Initial pass to level and settle concrete |

| Finish Blade | Narrower, sharper edges | Final pass to polish and harden surface |

| Combination Blade | Dual-purpose | Performs both float and finish duties |

| Clip-on Blade | Attaches over float blades | Used with pans for floating stage |

Trowel Pans

Trowel pans are circular metal plates attached beneath the blades. They’re typically used during the floating stage for more even pressure distribution and a flatter finish.

Applications of Power Trowels

Power trowels are commonly used across many construction and infrastructure projects. Here are some applications:

Commercial Flooring

Shopping malls, offices, and warehouses often require smooth, flat concrete floors that support high foot traffic or machinery. Power trowels help achieve dense, abrasion-resistant surfaces that are ready for polishing or coating.

Industrial Facilities

Factories and distribution centers benefit from the strength and durability provided by machine-troweled concrete, which must withstand heavy equipment and forklifts.

Residential Projects

Driveways, patios, and basements also benefit from power troweling, particularly when a smooth, decorative finish is required.

Infrastructure

Airports, parking garages, bridges, and tunnels often require large-scale concrete pouring and finishing. Ride-on power trowels are preferred for these projects due to their efficiency over large surfaces.

Step-by-Step Power Troweling Process

Using the correct timing and proper technique is absolutely essential to achieve the best, most professional results when finishing concrete.

Step 1: Wait for the Right Time

You can’t begin troweling immediately after pouring. The concrete must partially set—firm enough to support the weight of the machine but still moist on the surface.

Check using the footprint test: If your shoe leaves a 1–3 mm imprint, it’s ready.

Step 2: Begin Floating

Start with float blades or pans to:

- Flatten imperfections

- Embed aggregates

- Bring water and fine materials to the surface

- Work in overlapping paths and avoid spinning too fast initially.

Step 3: Finish Troweling

- Once floating is done and the surface stiffens, switch to finish blades.

- Increase blade pitch for more pressure

- Make multiple passes in alternate directions

- Watch for burnishing or blade marks

Step 4: Final Pass and Inspection

The final pass should leave a shiny, hard surface. Check the surface for any cracks, uneven areas, or missed spots and fix them right away.

Choosing the Right Power Trowel

Selecting the right power trowel depends on several key factors:

| Factor | Walk-Behind | Ride-On |

| Surface Area | Small to medium | Large-scale projects |

| Budget | Lower upfront cost | Higher investment |

| Operator Skill | Basic training | Skilled operation required |

| Accessibility | Better for tight spaces | Needs open, clear areas |

| Speed/Efficiency | Slower, more manual | High productivity |

Other factors include:

- Blade diameter

- Weight of the machine

- Power source (gas, diesel, electric)

- Blade pitch adjustability

- Safety features (deadman switch, guards)

Maintenance and Safety Tips

Maintenance

- Check blade wear regularly; dull or bent blades reduce effectiveness.

- Inspect the gearbox and belts for wear and tear.

- Change engine oil as recommended.

- Clean machine after each use.

Safety Tips

- Always wear PPE, including gloves, eye protection, and sturdy boots.

- Avoid using on overly wet or dry concrete

- Use the kill switch or deadman lever to stop the machine instantly

- Avoid sudden, sharp turns to maintain balance

- Never operate near the edges of elevated platforms without protection

Innovations in Power Trowel Technology

Modern construction demands efficiency and sustainability. Recent innovations in power trowels include:

- Battery-Powered Models: Zero emissions for indoor or confined space work.

- Hydrostatic Drive Systems: Offer smoother and more responsive control.

- Laser-Guided Trowels: For precision finishing and grading.

- Data Logging: Smart systems that record usage, fuel, and blade condition.

Power trowels have transformed the way concrete finishing is performed, offering speed, consistency, and professional-grade results. By understanding the working mechanism, types, and practical applications of power trowels, contractors and project managers can select the right model for their needs, save time, and ensure quality in every slab they pour.

From residential garages to massive industrial floors, the power trowel is the finishing tool of choice for anyone serious about concrete work. Investing in the right equipment and knowing how and when to use it makes all the difference in durability, aesthetics, and long-term performance of your concrete surface.