Concrete scarifiers are indispensable machines in surface preparation, capable of removing coatings, smoothing concrete, and restoring floor grip. At the heart of their operation lies the scarifier cage assembly, which holds and rotates various cutters designed for specific applications. Choosing the correct cage assembly is critical—it influences cutting performance, depth, finish quality, and tool lifespan across different surfaces.

Scarifier Cage Assemblies

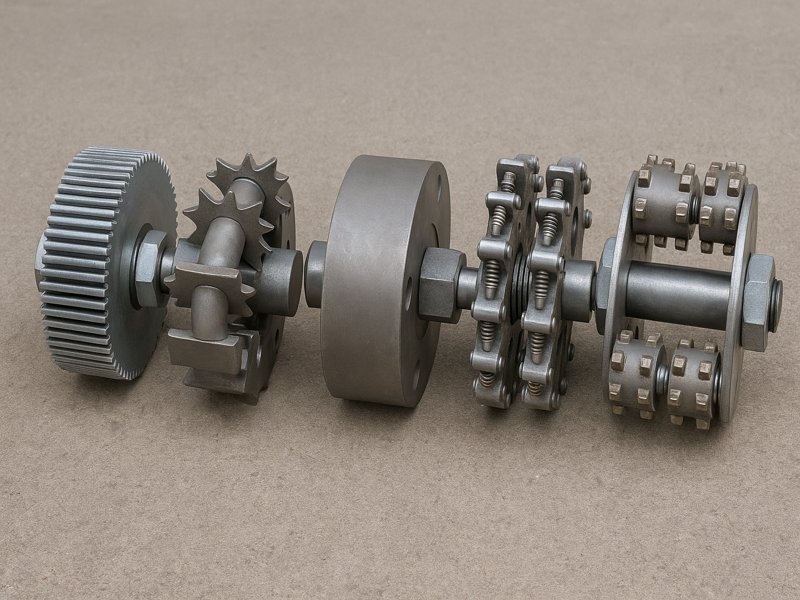

The cage assembly is the rotating drum or shaft on which flail-type cutters (also called milling cutters) are mounted. When powered by the scarifier’s motor, the cage spins at high speed, allowing cutters to chip, scrape, or plane the surface.

Key components of a scarifier cage assembly include:

- Drum or shaft core (steel or aluminum)

- Spacers and washers to control cutter arrangement

- Flail cutters, beam cutters, or needle rollers

- End plates and retaining bolts

Selecting the incorrect cage assembly can lead to inadequate cutting depth, a poor finish, or even machine damage. Thus, understanding the relationship between surface type and cage setup is essential.

Factors to Consider When Choosing a Cage Assembly

Selecting the right assembly involves more than just cutter type. Here are the most critical factors:

| Factor | Description |

| Surface Material | Concrete, asphalt, epoxy, metal, or tile |

| Surface Condition | Smooth, rough, cracked, coated, or soft |

| Removal Objective | Light cleaning, line removal, heavy milling |

| Desired Finish | Smooth, medium texture, or aggressively rough |

| Machine Compatibility | Shaft size, cutter width, and speed compatibility |

| Operating Environment | Indoor vs. outdoor, ventilation, debris removal |

| Durability Requirements | High-impact work demands more robust components |

Matching Cage Assemblies to Surface Conditions

Guidance for selecting scarifier cage assemblies by surface type.

Smooth Concrete Floors (Light Milling or Cleaning)

Recommended Assembly:

- Fine-toothed cutters (e.g., tungsten carbide milling cutters)

- Tight spacing with flat spacers

- Medium-speed rotation

These floors require minimal aggression to avoid over-cutting. Fine milling cutters leave a slightly textured surface ideal for recoating or polishing.

Use Cases:

- Light laitance removal

- Surface cleaning or profiling before epoxy

- Indoor warehouse floors

Pros:

- Minimal surface damage

- Uniform finish

- Ideal for indoor use

Old, Worn Concrete with Coatings

Recommended Assembly:

- Star-type tungsten cutters

- Loose cutter spacing with spring washers

- Medium to high speed

Aged concrete often contains old epoxy, adhesive, or rubber. Star cutters break through coatings efficiently without gouging the substrate.

Use Cases:

- Paint and epoxy removal

- Floor preparation for overlays

- Parking garages and warehouses

Pros:

- Aggressive removal of coatings

- Good balance between speed and control

Soft Asphalt or Bituminous Surfaces

Recommended Assembly:

- Wide flat cutters or beam cutters

- Soft metal alloy (for minimal gouging)

- Lower rotational speed

Asphalt is softer than concrete and can deform under heavy scarifiers. Beam cutters with wide contact zones ensure even removal without tearing the surface.

Use Cases:

- Line removal on roads

- Resurfacing damaged asphalt

- Runway or parking lot prep

Pros:

- Prevents deep grooves

- Maintains underlying integrity

- Less vibration

Uneven or Cracked Concrete

Recommended Assembly:

- Tungsten carbide flails with spring tension

- Open spacing to allow flex and movement

- Medium rotation speed

Cracked surfaces require cutters that can adjust dynamically without getting stuck. Spring-mounted flails adapt to variations in surface height.

Use Cases:

- Restoration of old floors

- Crack chasing

- Outdoor surface rehabilitation

Pros:

- Flexible across uneven ground

- Reduces machine bounce

- Good for prep prior to self-leveling

Thick Coatings, Concrete Buildup, or Heavy Milling

Recommended Assembly:

- Multi-point heavy-duty tungsten cutters

- Wide spacing, thick shaft

- High torque machine support

When removing heavy buildup, use heavy-duty cage assemblies that can withstand high stress. These setups prioritize removal speed over finish smoothness.

Use Cases:

- Demolition prep

- Grouting/concrete buildup removal

- Bridge and tunnel work

| Pros | Cons |

| √ Extreme cutting power | × Rough finish |

| √ Fast material removal | × Higher vibration |

| √ Durable and impact-resistant |

Technical Comparison

| Surface Type | Recommended Cutter Type | Cutter Spacing | Rotation Speed | Finish Quality | Removal Rate |

| Smooth Concrete | Fine milling cutters | Tight | Medium | Smooth | Low |

| Coated Concrete | Star tungsten cutters | Medium | Medium-High | Medium | Medium |

| Asphalt | Beam cutters | Wide | Low | Medium | Medium |

| Cracked Concrete | Tungsten flails (spring-mounted) | Open | Medium | Rough | Medium |

| Concrete Buildup | Multi-point tungsten | Wide | High | Rough | High |

Additional Selection Tips

Cutter Material:

- Steel Cutters – Low cost, short lifespan, for soft materials.

- Tungsten Carbide Cutters – Durable, aggressive, suitable for hard surfaces and thick coatings.

- Diamond Cutters (less common in cages) – High precision, expensive, used for fine surface prep.

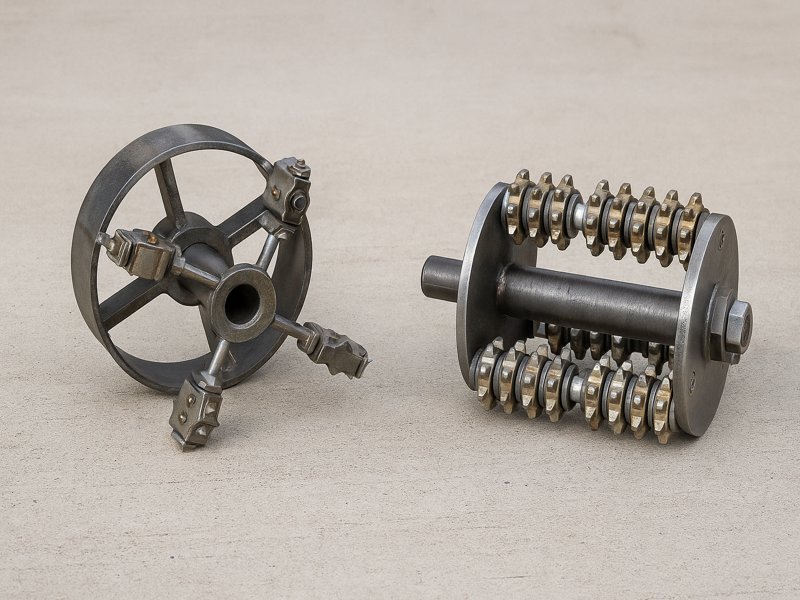

Drum Configuration:

- Single Cage Drum – Easier to install, suitable for light tasks.

- Double Cage Assembly – For wide machines and heavy-duty operations.

Shaft and Spacer Arrangement:

Varying the number of spacers and cutter arrangement alters the finish pattern.

- Tighter spacing = finer finish

- Wider spacing = faster removal

Machine Power Matching:

Ensure your scarifier’s motor output (HP/kW) matches the demands of the cage setup:

- Underpowered machines will bog down.

- Overpowered machines with light-duty cages may cause excessive wear.

Maintenance and Replacement Guidelines

Proper cage assembly selection reduces downtime and part failure, but maintenance is still essential:

- Inspect cutters daily for wear, chips, or missing flails.

- Check shaft bolts and spacers for secure attachment.

- Rotate or replace cutters as needed to maintain performance.

- Lubricate moving parts (especially spring-mounted flails) regularly.

- Avoid exceeding machine RPM recommendations, as it leads to premature damage.

Typical cutter lifespan varies:

| Cutter Type | Average Lifespan (m²) |

| Steel Cutters | 300–500 m² |

| Tungsten Cutters | 1,000–3,000 m² |

| Beam Cutters | 800–1,500 m² |

Custom Assemblies for Specialized Conditions

Some applications require custom cage assemblies. Examples include:

- Scarifiers used on steel decks or ship surfaces (non-sparking brass-coated cutters)

- Decorative concrete prep (precision spacing to create texture)

- Rail track restoration (cage attachments for grooved or uneven patterns)

Contact your equipment manufacturer or supplier for tailored cutter layouts if your job involves unique materials or pattern requirements.

Choose vendors that provide material data sheets and spec sheets.

Ask for case studies or user references for similar surface conditions.

Check for compatibility with major scarifier brands (Edco, Blastrac, Bartell, etc.).

Confirm supplier provides after-sales support and replacement parts.

Choosing the right scarifier cage assembly is essential for successful surface preparation across varying conditions. From smooth indoor concrete to rough outdoor asphalt, each scenario demands a specific cutter type, spacing, and assembly structure. Understanding your surface characteristics and matching them with the appropriate cage configuration will lead to more efficient operation, better finish quality, and longer tool life.