Whether you are preparing floors for industrial facilities, leveling slabs for residential homes, or laying large surfaces for commercial buildings, the screed technique you choose directly affects surface flatness, curing performance, labor efficiency, and long-term durability.

Modern construction projects have access to multiple screed systems—from basic manual screeds to high-output laser screeds—each offering different advantages depending on the scale, accuracy requirements, and budget. With the growing demand for tighter flatness tolerances and faster project cycles, understanding these options is crucial for project managers, contractors, and equipment buyers.

What Is Screeding and Why Does It Matter?

Screeding levels and smooths fresh concrete by removing excess material for a uniform surface. A quality screed ensures:

- Proper flatness and levelness (critical for flooring, tile installation, or coatings)

- Improved structural performance

- Reduced cracking

- Controlled slab thickness

- Higher productivity and better curing results

Poor screeding leads to uneven surfaces, increased rework, slow project schedules, and reduced floor durability. Therefore, selecting the right method is not purely equipment-based—it’s a strategic construction decision.

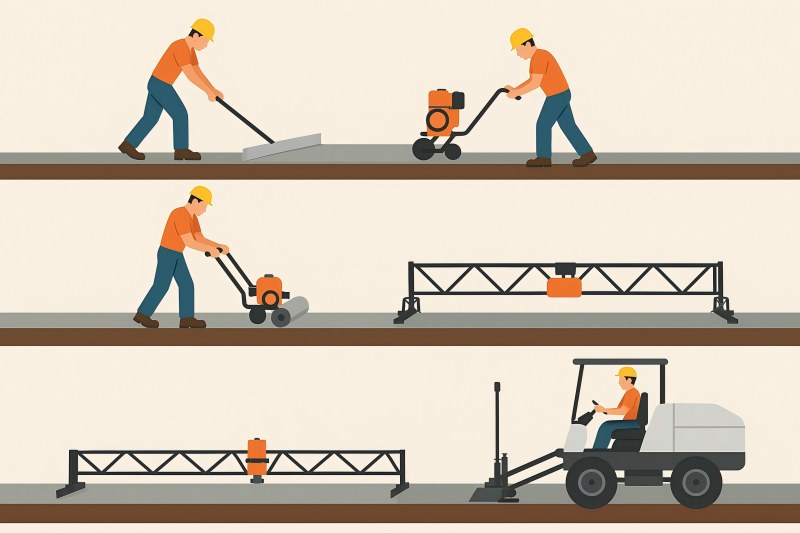

Overview of the Main Screed Methods

Modern construction uses several primary screed categories:

- Manual Screed (Hand Screed / Straightedge screed)

- Vibrating Screed (Engine-powered or electric)

- Roller Screed

- Truss Screed

- Laser Screed (Walk-behind or ride-on)

Each method differs in vibration power, finishing quality, manpower requirements, and cost.

Manual Screeding

How It Works

Manual screeding uses a long straightedge or aluminum screed bar pulled across the concrete surface by one or two workers. It does not include an engine or vibration system.

| Pros | Cons |

| Low cost and highly accessible | Labor-intensive |

| Suitable for very small areas | Difficult to achieve high flatness |

| Easy to transport and operate | Not effective for large pours |

| No compaction, higher risk of honeycombing or voids |

Best For

- Bathroom slabs

- Sidewalk patches

- Small residential floor repairs

- Tight-access areas where machines cannot enter

Vibrating Screed

How It Works

A vibrating screed consists of a long screed blade powered by an electric or gasoline motor. Vibration helps consolidate concrete as it levels.

| Pros | Cons |

| Faster than manual screeding | Requires trained operators |

| Provides uniform vibration and better surface consolidation | Not ideal for very large slabs |

| Reduces labor fatigue | Straightness and consistency depend on operator skill |

| Can handle medium-sized pours |

Best For

- Residential slabs and garages

- Small commercial floors

- General-purpose construction projects

Roller Screed

How It Works

A rotating tube (roller) spins across the concrete surface, striking off and smoothing concrete at a constant level. Some versions are electric or hydraulic.

| Pros | Cons |

| Excellent consistency | Limited vibration; may need extra compaction |

| Reduces operator fatigue | Not suitable for very large industrial floors |

| Works well on low-slump mixes | |

| Ideal for decorative or overlay concrete |

Best For

- Sidewalks, gutters, and curbs

- Parking lots

- Decorative stamped concrete

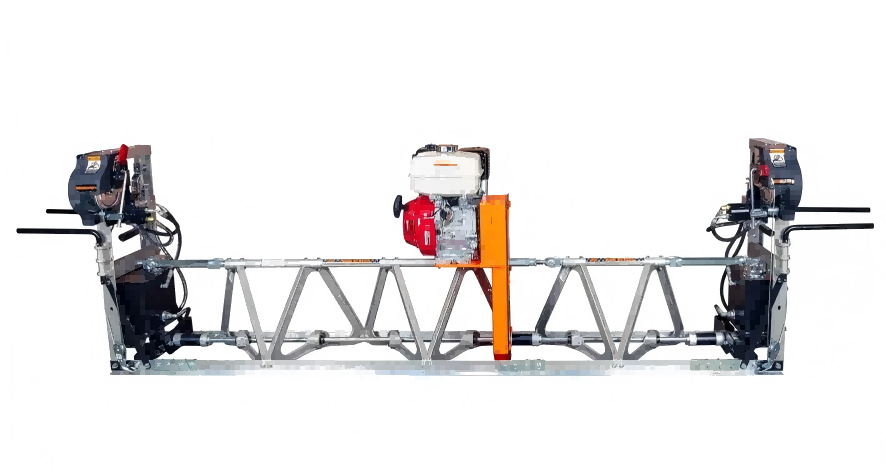

Truss Screed

How It Works

A long steel truss powered by gasoline engines spans wide slabs (8–20 meters). Vibrations travel along the truss to consolidate concrete.

| Pros | Cons |

| High vibration power | Requires skilled setup |

| Excellent for wide bays | Heavy and difficult to transport |

| Good flatness over long distances | Not optimal for tight spaces |

| Strong productivity for industrial flooring |

Best For

- Industrial floors

- Warehouses

- Large workshops

- Airport maintenance slabs

Laser Screed

Laser screeds are the most advanced, delivering the highest accuracy and largest output.

How It Works

A laser transmitter defines the reference level. The machine automatically adjusts the screed head to match that level, delivering near-perfect flatness.

| Pros | Cons |

| Best flatness (FF/FL ratings) | High equipment cost |

| Highest production rate in the industry | Requires open space and planning |

| Automatic level control | Training needed for operators |

| Reduces labor and rework | |

| Essential for superflat floors |

Best For

- Large malls and warehouses

- Logistics distribution centers

- Industrial flooring for forklifts

- Any project requiring FF/FL superflat specifications

Comparison Table: Screed Methods vs. Key Performance Factors

The following table compares the major screed methods based on quantitative project performance factors:

Performance Comparison of Screed Methods

| Screed Method | Daily Output (m²/day) | Typical Flatness Level | Labor Needed | Best Project Type |

| Manual Screed | 50–150 m² | Low | 3–4 workers | Small repairs, residential |

| Vibrating Screed | 200–500 m² | Medium | 2–3 workers | Small to medium floors |

| Roller Screed | 250–600 m² | Medium | 2 workers | Sidewalks, decorative |

| Truss Screed | 500–1500 m² | High | 3–5 workers | Industrial slabs |

| Laser Screed | 1500–4000 m² | Very High (Superflat) | 2–3 workers | Warehouses, distribution centers |

Cost Comparison and ROI Evaluation

Choosing a screed method also involves cost considerations. Below is an approximate breakdown.

Cost Factors by Screed Type

| Screed Type | Equipment Cost Range (USD) | Labor Cost / m² | Rework Risk | Overall Cost Efficiency |

| Manual Screed | $50–$300 | High | High | Low |

| Vibrating Screed | $500–$2,500 | Medium | Medium | Medium |

| Roller Screed | $1,000–$4,000 | Medium | Medium–Low | Medium–High |

| Truss Screed | $2,000–$12,000 | Medium–Low | Low | High |

| Laser Screed | $80,000–$400,000 | Low | Very Low | Very High |

Key insights:

- Manual screeding looks cheap upfront but is expensive in labor and rework.

- Vibrating screeds offer a strong balance for general contractors.

- Roller screeds excel when working on decorative or specialty surfaces.

- Truss screeds offer excellent productivity for medium–large slabs.

- Laser screeds demand high initial investment but deliver the best long-term ROI for large-scale commercial and industrial work.

Factors to Consider When Selecting a Screed Method

To choose the right system, evaluate the following criteria systematically:

Project Size and Concrete Volume

- Small projects (< 200 m²): Manual or vibrating screed

- Medium projects (200–1500 m²): Vibrating, roller, or truss screed

- Large projects (> 1500 m²): Laser screed or truss screed

If you frequently pour large floors, investing in automated screed systems dramatically improves profitability.

Flatness and Levelness Requirements

Common industry standards include:

- FF35–FF45 → typical warehouse floors

- FF50+ → superflat forklift aisles

- FF15–25 → home floors, parking slabs

Choose the screed based on the required result:

| Requirement | Recommended Screed |

| Basic flatness | Manual / Vibrating |

| Medium flatness | Roller / Vibrating |

| High flatness | Truss Screed |

| Superflat | Laser Screed |

Project Timeline and Output Speed

If speed is critical:

- Laser screeds and truss screeds are the highest-output systems

- Vibrating screeds suit medium-speed residential or commercial work

- Manual screeds significantly slow down projects

Accessibility and Site Conditions

- Narrow rooms, bathrooms: Manual screed

- Slopes or gutters: Roller screed

- Wide-open slabs: Truss or laser screed

- Uneven subgrade: Laser screed automatically adjusts level

Concrete Mix Design

Low-slump mixes (common for roadwork and overlays) favor:

- Roller screeds

- Truss screeds

- High slump mixes (more fluid) work well with:

- Vibrating screeds

- Laser screeds

Skilled Labor Availability

If your project location has limited skilled labor:

- Laser screeds reduce dependency on operator skill

- Roller screeds are beginner-friendly

- Manual screeds require experienced crews to maintain consistency

Budget and ROI

Ask:

- Will the project volume justify a laser screed rental/purchase?

- Is rework a major cost concern?

- How much manpower can you allocate?

Selecting a lower-cost system may increase total expenses due to:

- More labor hours

- Greater surface defects

- Slower progress

Example Scenarios: Which Screed Should You Choose?

Scenario A: Residential Home Slab (120 m²)

- Choose: Vibrating Screed

- Why: Cost-effective, portable, good finish quality.

Scenario B: Decorative Sidewalk With Low-Slump Mix

- Choose: Roller Screed

- Why: Avoid over-vibration and maintain surface texture consistency.

Scenario C: Warehouse Floor (2,000 m²) Requiring High FF/FL

- Choose: Laser Screed

- Why: Automatic leveling, high throughput, best flatness.

Scenario D: Industrial Workshop Slab (1,000 m²)

- Choose: Truss Screed

- Why: High vibration power and wide coverage without laser-level precision needs.

Scenario E: Very Tight Indoor Area (50 m²)

- Choose: Manual Screed

- Why: Machines cannot operate easily in confined spaces.

When to Rent vs. Buy Screed Equipment

Rent if:

- You only handle large projects occasionally

- You’re testing different systems

- You want to avoid maintenance and storage costs

Buy if:

- You pour large slabs frequently

- You want consistent availability

- You aim to reduce long-term cost per square meter

Step-by-Step Guide: How to Choose the Right Screed

Follow this structured method:

Step 1: Define project size and surface requirements

Step 2: Evaluate flatness tolerance and client expectations

Step 3: Assess available labor and skill level

Step 4: Consider site accessibility and mix design

Step 5: Compare cost vs. productivity

Step 6: Select the screed with the best balance of quality, speed, and ROI

This systematic approach ensures you choose a method aligned with technical needs and project profitability.

Choose the Screed That Matches Your Goals

The right screed method depends on your project size, flatness requirements, labor availability, and budget. Manual and vibrating screeds offer flexible solutions for small-scale projects, while roller screeds excel in specialty and decorative work. Truss screeds provide robust performance for industrial slabs, and laser screeds stand as the gold standard for precision and efficiency in large commercial projects.

By understanding each system’s strengths and limitations—and evaluating your project’s technical demands—you can confidently select a screed method that ensures smooth, durable, and high-performance concrete surfaces while maximizing productivity and cost efficiency.