Concrete Mixer Manufacturer

We deliver durable, efficient, and versatile mixing solutions tailored for construction sites of all sizes.

Our mixers are primarily drum-based designs, producing towed, wheelbarrow and stand mixers to ensure consistent mixing performance, reduce labor costs and increase on-site productivity.

- 80-500L Drum Volume

- Electric, Gasoline and Diesel Power Optional

- Complete Source for Concrete Mixer Accessories

- Custom OEM for Concrete Mixer Needs

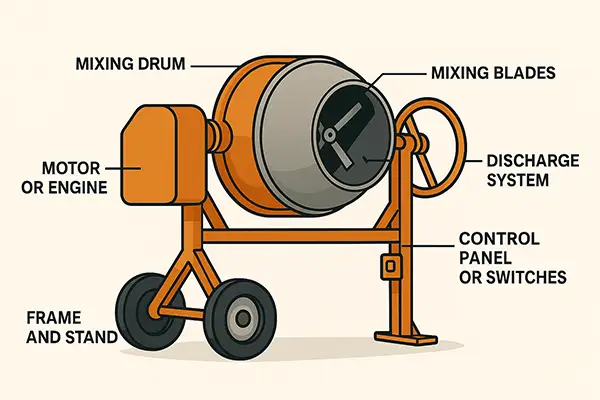

Concrete Mixer Components

Mixing Drum

- Steel mixing drum rotates to blend materials, available in 80–500L capacities for durability and consistent performance.

Motor or Engine

- Powers drum rotation using electric, gasoline, or diesel engines, directly affecting efficiency and application suitability.

Frame and Stand

- Provides structural support with handles, wheels, and mounts to ensure both mobility and operational stability.

Mixing Blades

- Welded or bolted inside the drum, the blades ensure uniform mixing of all concrete materials.

Discharge System

- Mechanism for emptying mixed concrete, such as a tilting drum, discharge chute, or manual lever.

Control Panel or Switches

- Used for operating electric mixers, featuring on/off buttons, speed control, and built-in safety switches.

We Provide 3 Types of Concrete Mixers

Towable Concrete Mixer

- Maximum capacity up to 500L

- Powered by gasoline and diesel engines

- Durable cast iron ring gear for extended service life

- Tow bar design allows convenient towing and mobility

Wheelbarrow Concrete Mixer

- Middle drum sizes (125–180L)

- Gasoline engine driver

- Integrated with a wheelbarrow-style frame

- Highly portable for moving short distances

Rack Concrete Mixer

- Small sized drums 100L

- Electric motor driver

- Mounted on a fixed steel rack or stand

- Suitable for interiors or tight spaces

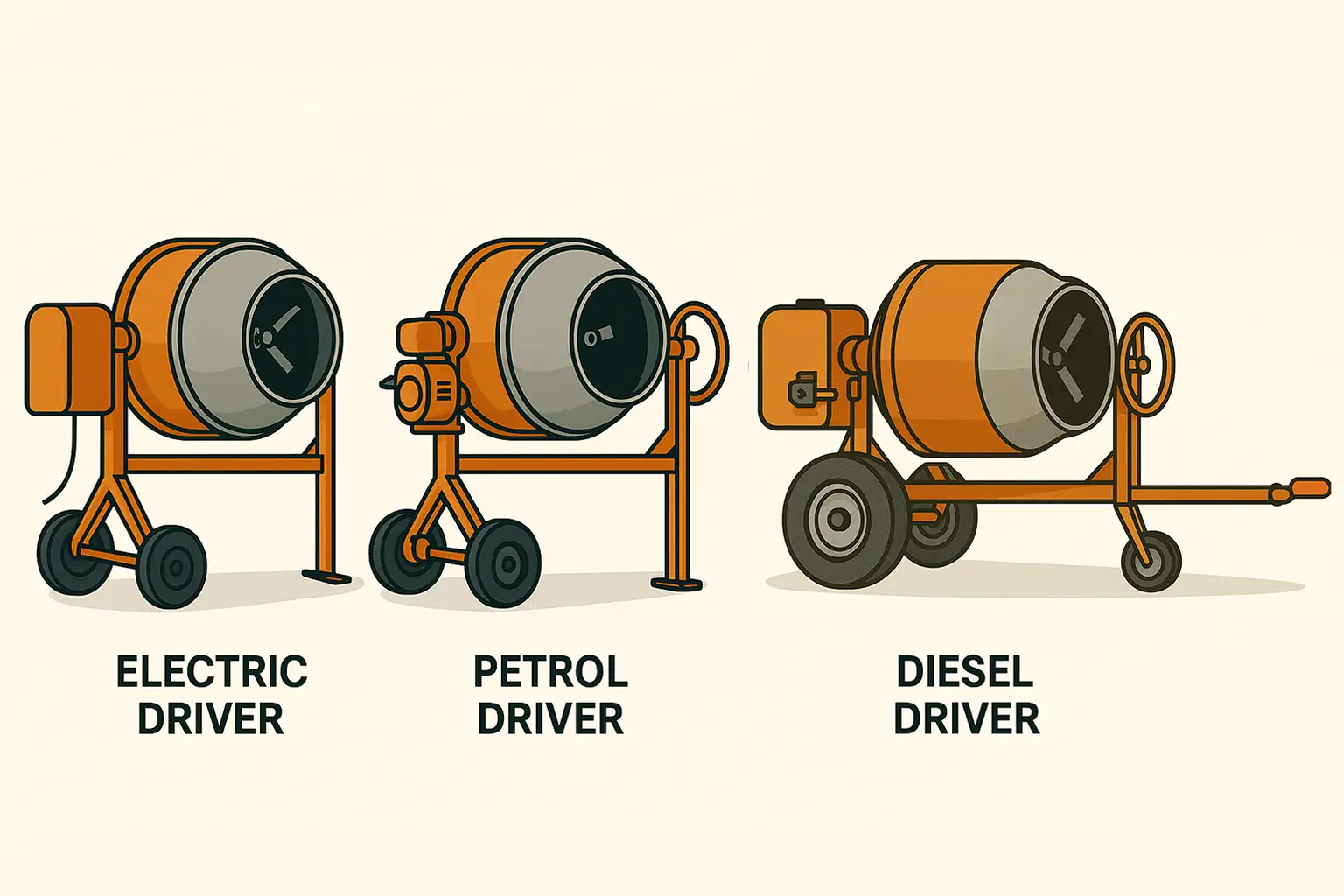

By Power Driver

Our concrete mixers feature electric, petrol, or diesel power drivers for flexible, efficient, and reliable mixing across varied job site conditions.

Electric Motor

- Powered by electricity(Typically 110V, 220V or 380V)

- It operates quietly and emission-free

- Ideal for indoor, urban, or small-to-medium projects

Petrol Engine

- Powered by a gasoline engine

- Good for tougher mixes and moderate workloads

Diesel Engine

- Powered by a diesel engine

- Designed for heavy loads and intensive mixing tasks

Custom Drum Volume

- The volume of our drum is 80-500L. Its mixing capacity is related to the total capacity, usually about 40%-60% of the total capacity. For example, a 350L drum mixes about 140-200L of concrete.

- Need a larger drum capacity?

What Types of Mixtures Can Concrete Mixer Mix?

Concrete mixers can handle standard concrete, mortar, render mix, and self-leveling mortar for structural, masonry, finishing, and flooring applications.

Standard Concrete

- Cement + Sand + Stone + Water (Additives can be added)

- Ideal for structural engineering such as foundation, beams, columns, and floors.

Mortar

- Cement + Sand + Water (sometimes with lime or admixtures)

- A binding material for bricklaying, tiling, and plastering.

Sand and Cement Render Mix

- Fine sand+ Portland cement+ water

- Provides a protective and decorative finish to brick, block, or concrete walls.

Self-leveling Mortar

- Special cement + fine sand + polymer

- Used for ground leveling, suitable for floor heating, before laying floor.

Featured Products

SM 260-500 Series Towable Concrete Mixer

- Drum Volume: 260-500L

- Productivity: 6-22m³/h

- Mixing Speed: 30r/min

- Driving: Manual push

SMT100 Rack Type Concrete Mixer

- Drum Volume: 100L

- Drum Speed: 26.6r/min

- Voltage: 110, 230, 380V

- Engine: Electric

SM 80-200 Series Towable Concrete Mixer

- Drum Volume: 80-200L

- Mixing Speed: 28-30r/min

- Voltage: 110V,230V,380V

- Motor Speed: 2800r/min

SMT125-180 Series Wheelbarrow Concrete Mixer

- Drum Volume:125-180L

- Mixing Speed: 30r/min

- Voltage: 110V,230V,380V

- Motor Speed: 2800r/min

Applications

Construction Projects

Concrete mixers are essential for building roads, bridges, buildings, and infrastructure, ensuring consistent concrete quality for columns, beams, slabs, and other structural elements on-site.

Foundations

Concrete mixers deliver uniform concrete for strong, stable foundations, including footings, basements, and slabs, supporting the entire weight of buildings and preventing structural settlement or shifting.

Home Projects

Ideal for DIY tasks like patios, sidewalks, garden paths, and fence posts, concrete mixers offer convenience and precision for small residential construction or renovation jobs.

Repair and Maintenance

Used for fixing cracked pavements, reinforcing damaged concrete surfaces, or patching walls, mixers ensure proper blend and consistency for durable, lasting repair solutions.

FAQ

Are portable mixers electric or fuel-powered?

They come in electric, petrol, and diesel-powered versions.

What’s the recommended duration for mixing concrete?

Most portable mixers take 3 to 5 minutes per batch, depending on mix type and load size.

How do I clean a portable concrete mixer?

Rinse the drum with water immediately after use and scrape off any hardened concrete with a brush or chisel.

What safety precautions should I follow?

Always wear gloves and safety goggles, ensure the mixer is on stable ground, and never reach into a running drum.

Can I store the mixer outdoors?

It’s best to cover or store it in a dry place to prevent rust and wear.