Ground compaction is a crucial process in construction, road building, and landscaping. It increases the load-bearing capacity of the soil, reduces settling and water seepage, and enhances the stability of structures.

One of the most common tools used for this purpose is the vibratory plate compactor, known for its simplicity, versatility, and efficiency in compacting granular and mixed soils.

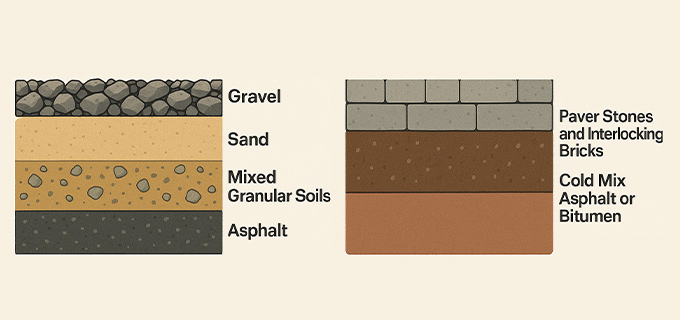

Types of Ground Materials Suitable for Vibratory Plate Compactors

The type of ground material significantly impacts compaction. Plate compactors work best on granular soils, which respond well to vibration and displacement for effective densification. Here are the main types:

Gravel and Crushed Stone

Suitability: ★★★★★

Best Use: Base layers for roads, driveways, patios, and walkways.

Vibratory plate compactors are highly effective for gravel and crushed aggregates. These materials contain angular particles that lock together when vibrated. A forward or reversible plate compactor can quickly compact these aggregates in thin layers (about 4–8 inches at a time).

Precaution:

- Add water if the material is dusty to reduce airborne particles.

- Avoid over-compaction, which may break down the stone particles.

Sand

Suitability: ★★★★★

Best Use: Bedding for pavers, playground foundations, and base layers.

Sand, especially clean, dry sand, compacts exceptionally well with plate compactors due to its granular nature. Coarse sand responds better to compaction than fine sand because of better drainage and less cohesion.

Precaution:

- A slight moisture content improves compaction; too much water reduces its effectiveness.

- Avoid compacting sand layers thicker than 6 inches in one pass.

Mixed Granular Soils

Suitability: ★★★★☆

Best Use: Road shoulders, sub-base, trench backfill.

These soils combine sand, gravel, and silt. When the granular component is dominant (over 50%), vibratory plate compactors work efficiently. Mixed granular materials often require multiple passes for uniform compaction.

Precaution:

- Test moisture content before compacting; optimal moisture is crucial.

- Excessive fines (silt or clay) may reduce vibration effectiveness.

Asphalt

Suitability: ★★★★☆

Best Use: Patch repair, driveways, paths, parking lots.

Plate compactors, particularly those with water tanks, are useful for light asphalt compaction, such as repairing potholes or installing new driveways. Vibration ensures bonding between new and existing layers.

Precaution:

- Use water spray to prevent hot asphalt from sticking to the plate.

- Avoid prolonged vibration in one spot, which may cause surface damage.

Paver Stones and Interlocking Bricks

Suitability: ★★★★☆

Best Use: Patios, walkways, and plazas.

When installing concrete pavers, a plate compactor is used to seat the bricks into the bedding sand and to compact jointing sand into the seams. Use a rubber mat attachment to prevent damaging the paver surface.

Precaution:

- Always attach a paver pad to the base plate.

- Sweep fine joint sand across the pavers before compacting.

Cold Mix Asphalt or Bitumen

Suitability: ★★★☆☆

Best Use: Temporary patches or minor road repairs.

Cold mix is softer and less cohesive than hot mix asphalt. While not ideal, plate compactors can handle light applications of cold mix in small areas.

Precaution:

- Compact in thinner layers.

- Avoid using on steep gradients where sliding may occur.

Soil with Clay Content (Low to Moderate)

Suitability: ★★☆☆☆

Best Use: Light backfill or landscaping in small projects.

Clayey soils are not ideal for plate compactors because they are cohesive, absorbing vibration rather than compacting. However, soils with low to moderate clay content and good moisture control may still be compacted with extra effort.

Precaution:

- Use short passes and higher-frequency compactors.

- Check for proper moisture—too dry or too wet impairs compaction.

Ground Materials Not Recommended for Plate Compaction

There are also materials that should not be compacted using plate compactors, or require specialized machines like rammers or rollers instead:

| Ground Material | Reason | Recommended Equipment |

| High Plasticity Clays | Too cohesive, absorbs vibration | Sheep ‘s-foot rollers, rammers |

| Peat or Organic Soils | Compresses easily but rebounds over time | Soil replacement recommended |

| Silts with High Water | Prone to pumping and instability when vibrated | De-watering + compaction rollers |

| Frozen Soil | Cannot be compacted reliably | Avoid until thawed |

| Contaminated Soil | May require special handling and cannot vibrate | Excavation + stabilization |

Key Factors to Pay Attention to When Using a Plate Compactor

Operating a vibratory plate compactor safely and efficiently requires attention to both material characteristics and machine operation. Here’s what you must consider:

Moisture Content of Soil

Optimal moisture is the key to successful compaction. Too little water leads to poor density, while too much creates slurry-like conditions.

- Use the “hand squeeze test” for field checks.

- To be more precise, think about utilizing a soil moisture meter.

Layer Thickness (Lift Depth)

- Limit each lift to 3–6 inches (75–150 mm) for maximum compaction efficiency.

- Compact in multiple thin layers rather than one thick layer.

Number of Passes

- Light-duty plates: 3–5 passes per lift.

- Heavy-duty or reversible plates: 2–4 passes.

- Use a nuclear densometer or Proctor test for exact compaction measurements.

Direction and Overlap

- Compact in a systematic, overlapping path—typically 1/3 plate width overlap.

- Avoid irregular or crisscross patterns.

Soil Gradation and Particle Size

- Well-graded granular soils compact best.

- Uniform soils may require additives or multiple compaction methods.

Equipment Type and Specifications

Select the right plate compactor based on:

| Application | Recommended Plate Type |

| Landscaping, pavers | Forward plate with water tank + pad |

| Base prep, driveways | Reversible heavy-duty plate |

| Asphalt patching | Forward plate with water tank |

Look at parameters like centrifugal force, frequency (vpm), and plate size to match the job.

Safety Considerations

- Wear hearing protection, gloves, and steel-toe boots.

- Avoid loose clothing around moving parts.

- Let the machine cool before refueling.

- Never use on inclines >20° without proper support.

Troubleshooting Common Compaction Problems

Even when using the right equipment, compaction may not meet expectations. Here’s how to identify and address issues:

| Problem | Likely Cause | Solution |

| Soil remains loose | Too dry or too wet | Adjust moisture content |

| Soil cracks or lifts | Over-compacted or wrong material | Reduce vibration or layer depth |

| Pavers shift after compaction | No padding or improper sand base | Use rubber mat, reset base |

| Vibrations ineffective | Wrong soil type | Use roller or rammer instead |

| Sticking under plate | Sticky soil or hot asphalt | Use water spray or release agent |

Summary: Matching Soil Types with Plate Compaction

| Soil Type | Plate Compactor Suitability | Notes |

| Gravel & Aggregates | Excellent | Angular particles lock under vibration |

| Sand | Excellent | Slight moisture helps binding |

| Mixed Granular Soils | Good | Requires moisture control |

| Asphalt (hot/cold) | Good (with water tank) | Use proper pad to prevent sticking |

| Pavers | Good (with mat) | Ensure joint sand is present |

| Clay Soils | Poor | Use only with light clay content |

| Silty or Organic Soil | Very Poor | Use other compaction methods |

Vibratory plate compactors are versatile machines that shine when used on granular, non-cohesive soils like sand, gravel, and mixed aggregates. They also perform well in asphalt work and paver installations when used with appropriate attachments and techniques. However, their effectiveness drops when working with highly cohesive or wet soils, which may require alternative equipment or additional soil preparation steps.

By understanding the types of materials suitable for plate compaction and following best practices in layer control, moisture management, and machine operation, contractors and builders can ensure solid, long-lasting results in a wide range of construction and landscaping projects.