How to Use a Poker Vibrator Correctly: Step-by-Step for Best Compaction

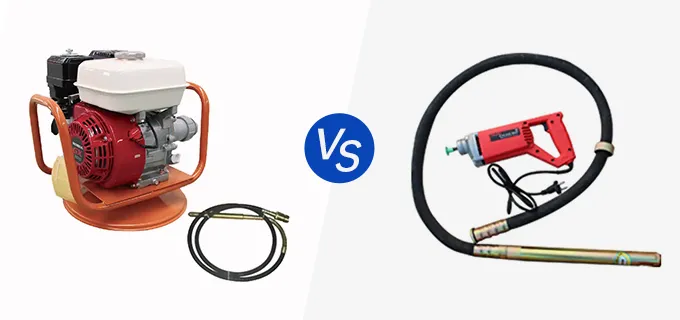

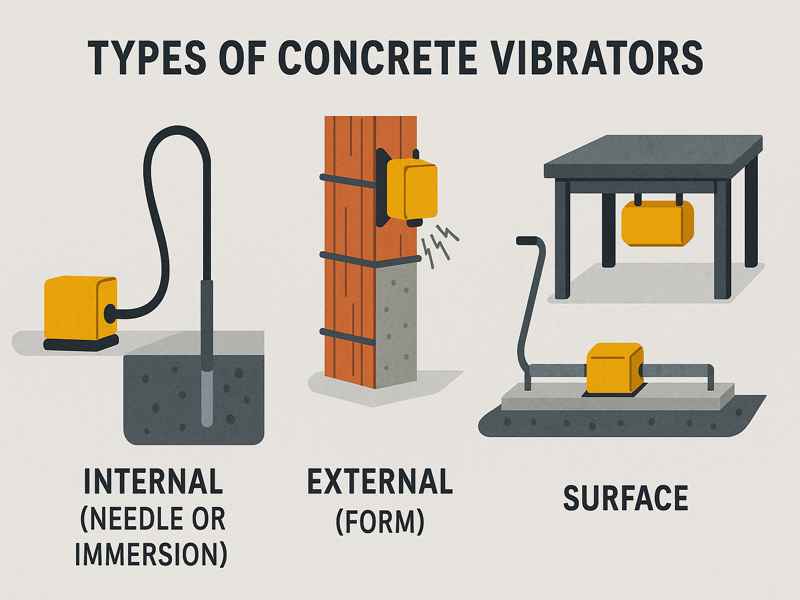

Concrete forms the foundation of modern construction, yet even the most robust mix can fail without proper compaction. One of the most efficient tools for internal concrete compaction is the poker vibrator (also known as a needle or immersion vibrator). Despite its apparent simplicity, incorrect use can lead to honeycombing, segregation, voids, or compromised structural integrity. Role of a Poker Vibrator in Concrete Compaction Before learning how to use it, you should first understand what a poker vibrator does and why it’s important. What Is a Poker Vibrator? The poker vibrator is composed of: A vibrating head (the poker or needle) A flexible shaft connecting the head to a motor A drive unit powered by electricity, compressed air, or a petrol/diesel engine Once the vibrating poker is inserted into wet concrete, it creates high-frequency oscillations that: Eliminate entrapped air Reduce voids and pockets Allow concrete to settle into formwork fully Improve inter-particle bonding and surface finish Pre-Operation Checklist: Preparing for Safe and Effective Use Inspect the Equipment Before starting: Check the poker head for damage or wear. Ensure the flexible shaft is not kinked or leaking oil. Test the motor function and RPM. Confirm the power source (fuel or electrical) is appropriate and safe. Safety Equipment Always wear: Safety boots Eye protection Gloves Ear protection (for petrol/diesel models) High-visibility clothing if on-site Concrete Pouring Preparation Make sure the formwork is secure and leak-free. Concrete should be sufficiently workable (not too stiff). Avoid delays between pouring and compaction. Step-by-Step Guide: How to Use a Poker Vibrator Properly Let’s break down the compaction process step by step: Step 1: Start the Motor and Test the Vibrator Turn on the motor (plug in or start fuel engine). Let it run briefly to ensure stable vibration performance. Hold vertically and touch surface gently to check vibration strength. Tip: The standard vibration frequency ranges between 12,000–17,000 vibrations per minute (vpm). Step 2: Insert the Poker Vertically into the Concrete Insert vertically and not at an angle. Let the poker descend by its own weight—do not force it. Do not move the poker sideways through the concrete. Why vertical? It avoids disturbing reinforcement and prevents segregation. Step 3: Penetrate in Regular Intervals and Overlap Zones Insert the poker at evenly spaced intervals, typically 8–10 times the diameter of the poker head. Make sure each new insertion overlaps the previous area of vibration by at least 50 mm. Poker Head Diameter Max Spacing Between Insertions 25 mm 200 mm 40 mm 320 mm 60 mm 480 mm Tip: For walls or columns, insert at 300–400 mm centers for uniform results. Step 4: Vibrate Each Spot for the Correct Duration The optimal vibration time per insertion depends on the slump, concrete type, and formwork size. Slump (mm) Suggested Vibration Duration 20–40 mm 10–20 seconds 60–90 mm 5–10 seconds >100 mm 3–5 seconds You can confirm proper compaction when The release of air bubbles ceases The surface becomes shiny or smooth The tone of the motor changes (indicating reduced resistance) Warning: Over-vibration can lead to segregation—where heavier aggregates sink and cement slurry rises. Step 5: Gradually Withdraw the Poker Vertically Slowly pull up the poker at ~3 cm/sec. This lets concrete fill poker void. Avoid sudden removal, which can trap air and leave holes. Step 6: Repeat Across the Entire Pour Area Continue the insertion–vibration–withdrawal cycle across the slab or column. Ensure each area is compacted uniformly. Watch for honeycombs or inconsistent surface textures. Compaction in Different Structures: Tips & Best Practices Concrete Slabs Use larger poker heads (50–60 mm) for thick slabs. For thin slabs (<150 mm), consider using vibrating screeds instead. Watch edge zones—ensure full compaction near formwork. Columns & Walls Start vibrating from the bottom up. Insert poker in layers no more than 450 mm thick. Avoid touching reinforcement to prevent rebound effects. Beams and Foundations Vibrate both around and within the rebar. Watch out for rebound vibration when in contact with dense steel. Common Errors to Avoid When Operating Poker Vibrator Mistake Impact Not vibrating at all Weak, porous concrete; honeycombs Over-vibrating Aggregate segregation; reduced strength Vibrating only the surface Voids remain in lower layers Forcing the poker down Can disturb formwork or reinforcement Using the wrong head size Poor compaction or excessive effort Inconsistent insertion depth Uneven strength and density Reminder: Always follow the project’s specifications for compaction time, spacing, and vibration type. Maintenance Tips for Long-Term Poker Vibrator Use Proper maintenance extends lifespan and keeps performance consistently reliable. After each use: Clean the poker head thoroughly to remove concrete buildup. Weekly checks: Inspect cables, hoses, and flexible shafts for wear. Monthly servicing: Lubricate internal bearings and inspect motor performance. Storage: Keep in dry, clean areas to avoid rust and moisture damage. Safety Considerations While Using Poker Vibrators Electrical Safety Use proper ground-fault protection (GFCI). Avoid water exposure with electric vibrators. Vibration-Related Injuries Limit continuous exposure to Hand-Arm Vibration Syndrome (HAVS). Use padded gloves and rotate workers if compacting large areas. General Hazards Watch out for tripping hazards from cords and shafts. Maintain proper footing, especially when standing on formwork or scaffolding. When to Use Alternatives to Poker Vibrators Poker vibrators are not always ideal. Use alternatives in these cases: Situation Alternative Very thin slabs (<100 mm) Vibrating screed Precast elements with thin walls External shutter vibrator Large area pours Surface vibrators or rollers Precision Compaction Equals Durable Concrete Using a poker vibrator correctly is about precision, patience, and technique. Skipping or misapplying compaction can undo all the effort put into mixing and pouring concrete. By following the step-by-step guide above—from insertion angle and spacing to vibration duration—you’ll ensure your concrete is solid, void-free, and long-lasting. Whether you’re working on a foundation, column, or floor slab, proper poker vibrator use is key to reliable structural performance.